| • With detection confidentiality (unique code can be provided) •Strong anti-interference, safety and reliability. •Safety level PLe can be achieved by using safe dual-channel output technology. •Effectively prevent false positives or false negatives, or artificial abnormal triggers. •Can be used with the safety door. |

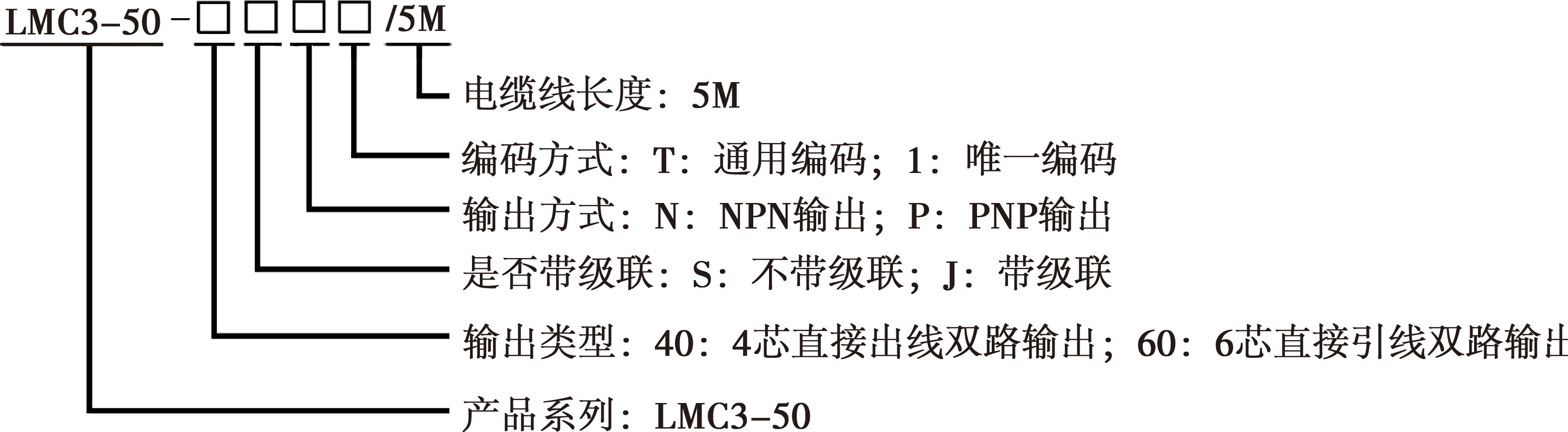

| Ordering information |

Switch model | Specification | Output method | Encoding method |

LMC3-50-40SNT/5M | 4-core direct wiring with dual output 5M cable | NPN | Universal encoding |

LMC3-50-40SN1/5M | Unique encoding | ||

LMC3-50-40SPT/5M | 4-core direct wiring with dual output 5M cable | PNP | Universal encoding |

LMC3-50-40SP1/5M | Unique encoding | ||

LMC3-50-60JNT/5M | 6-core direct wiring with dual output and cascading 5M cable | NPN | Universal encoding |

LMC3-50-60JN1/5M | Unique encoding | ||

LMC3-50-60JPT/5M | 6-core direct wiring with dual output and cascading 5M cable | PNP | Universal encoding |

LMC3-50-60JP1/5M | Unique encoding |

| Model Description |

| Technical parameter |

Safty standard Mean Time to Dangerous Failure (MTTFd) (years) | ISO13849-11EC/EN60947-5-1IEC/EN60947-5-3 ≥30 years |

Safety classification | Class 4 switch according to IS0 13849-1/suitable for PLe/PL |

Certification | CE |

Horizontal working distance | Conduction, min:10mm |

Vertical working distance | Conduction, min:8mm |

Operating voltage | 24V DC±15% |

Operating current | 150mA |

Response time | 60ms |

The protection grades | IP65, IP67 (customized) |

Operating frequency | lHZ |

Working temperature | -10~+55℃ |

Relative humidity | 5%~95% |

Material | Flame-retardant thermoplastic |

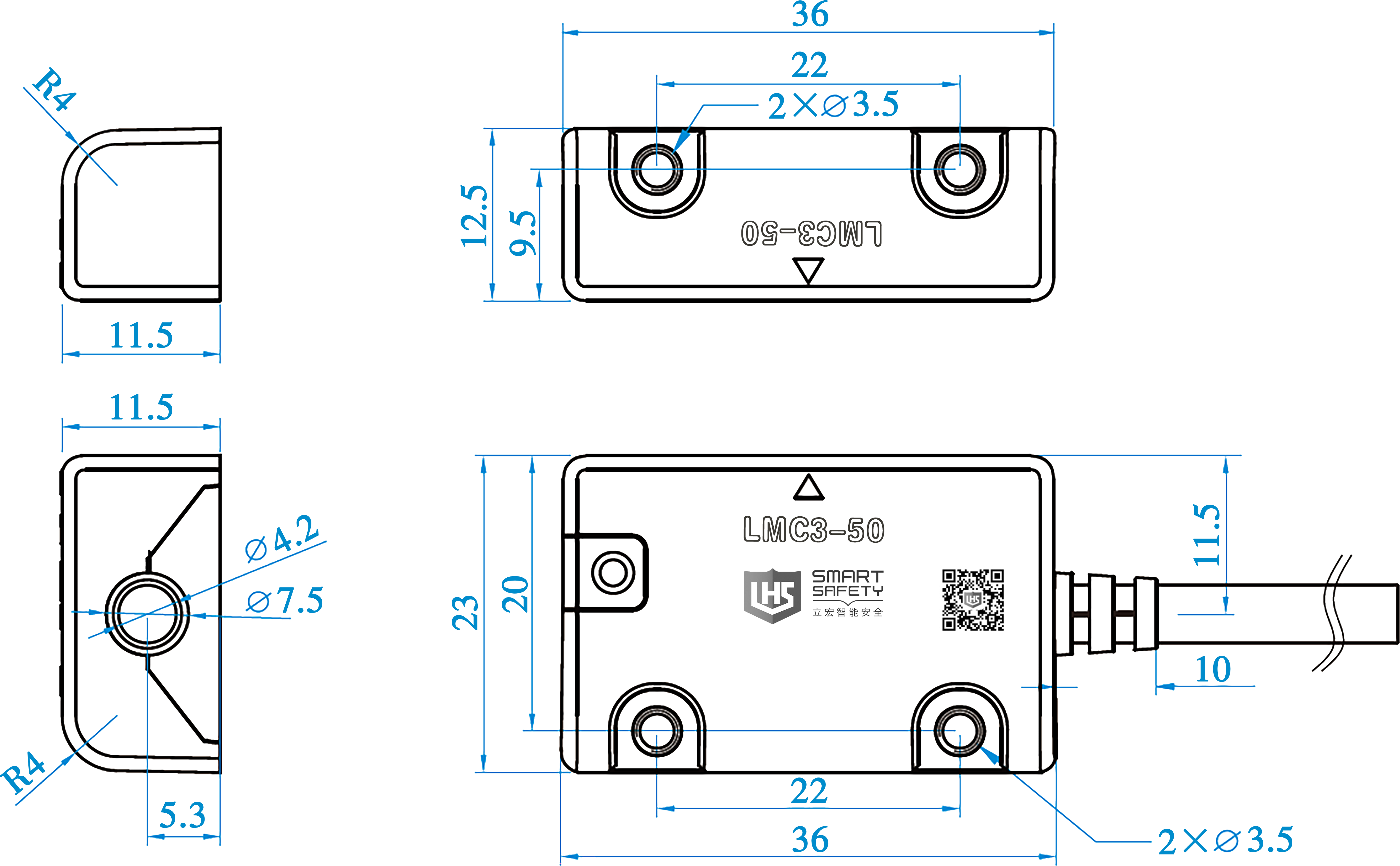

| Shape and installation dimensions |

|  |

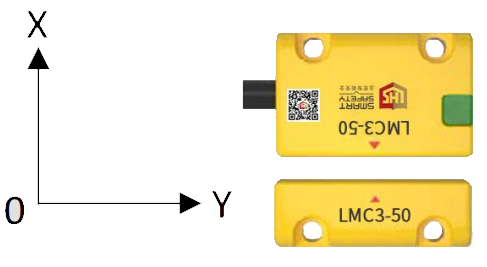

| Approach pattern of LMC3-50 switch |

|  |

LMC3-50 switch induction distance

LMC3-50 switch induction distance

Misalignment deviation | breakover | disconnect | Alignment signal | |

Horizontal alignment | The deviation is within 4 mm in the X direction. | Y direction induction 0~10mm | Y direction induction distance > 25mm |  |

| The deviation is > 5mm and < -5mm in the x direction. | Not recommended | |||

Vertical alignment | The deviation is within 4mm of soil in X direction. | Z direction induction distance 0~8mm | Z direction induction distance > 23mm |  |

| The deviation is > 5mm and < -5mm in the x direction. | Not recommended | |||

| Hookup |

Two-way output with cascade connection diagram | serial number | Signal definition | colour | explain |

| 1 | 24V | palm | Power supply positive |

2 | 0V | blue | Negative power supply | |

3 | output1 | black | Safety output 1 | |

4 | output2 | white | Safety output 2 | |

5 | input1 | green | Cascade input 1 | |

6 | input2 | yellow | Cascade input 2 |

Legend of connection between RFID switch and safety relay module (dual output)

Legend of connection between RFID switch and safety relay module (dual output)

|

| RFID switch approach pattern |

Led display | Signal state | State description | |

input | output | ||

The red light is always on. | Yes/No. | break | No actuator or incomplete alignment (universal coding) |

The red light is on for 1 second and then flashes twice (alternately). | Yes/No. | break | No actuator or incomplete alignment (unique code) |

Red light flashing at 4Hz | effective | break | Output overload |

Green light flashes at 1Hz. | be invalid | break | No input signal (dual output is not applicable) |

The green light is always on | effective | through | Induction is normal |

Alternate flashing of traffic lights | effective | break | Label is not registered. |

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright © Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing