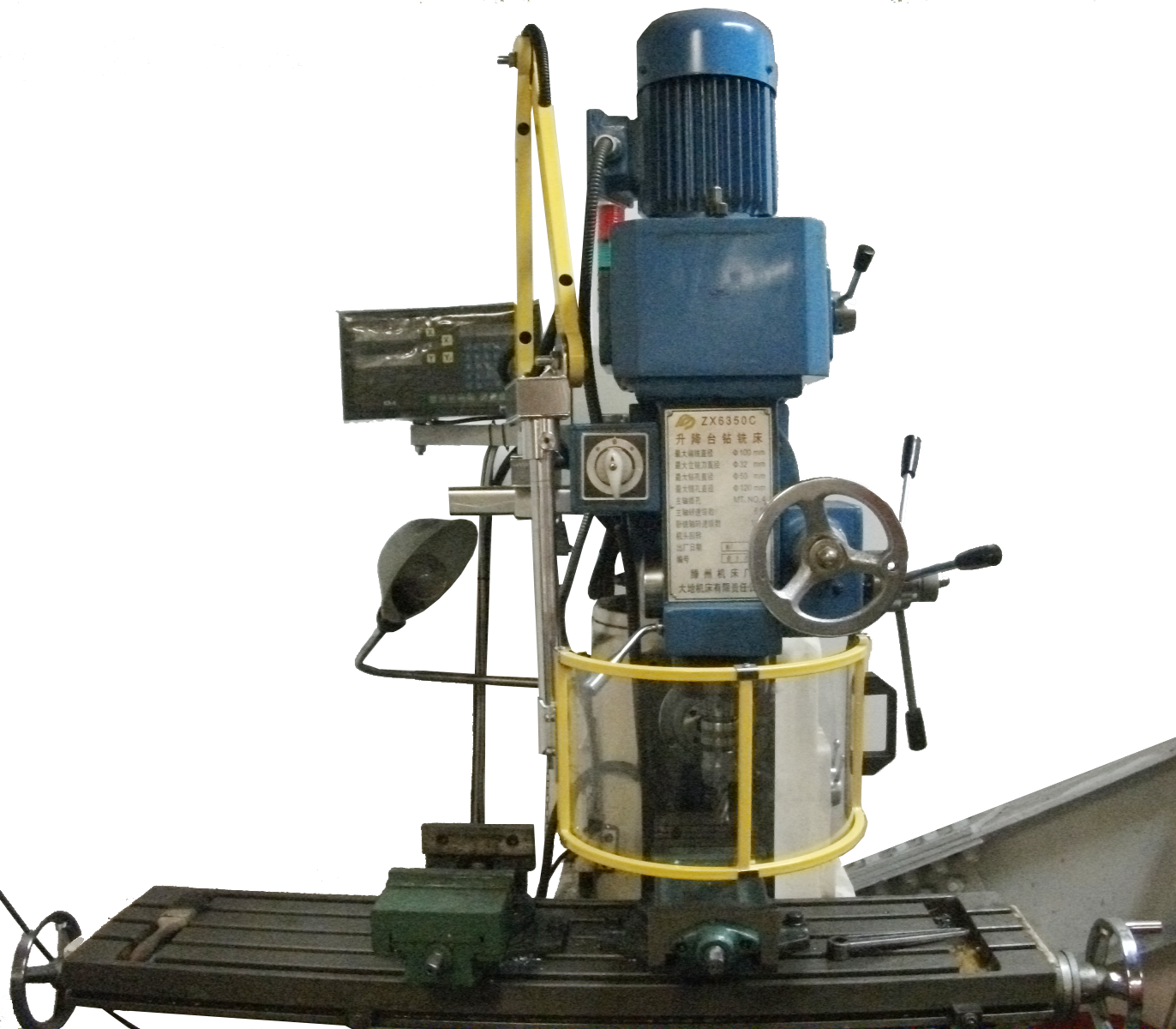

| ·During the operation of the drilling machine, hot debris and sparks are generated in the operation area, and the roating parts of the machine will endanger the safety of personnel; ·Improve the safety performance during the operation of the drilling machine, prevent the operator's hands from directly contacting the high-speed rotating drill bit, prevent accidental mechanical injury, and protect the operator's personal safety. ·Safety control system Comply with (GB/T 16855.1-1997) Class 1 or Class 3 stop requirements; comply with the relevant regulations and requirements of GB5226.1-2002 10.7, and GB 16754; |

Drilling machine protection selection

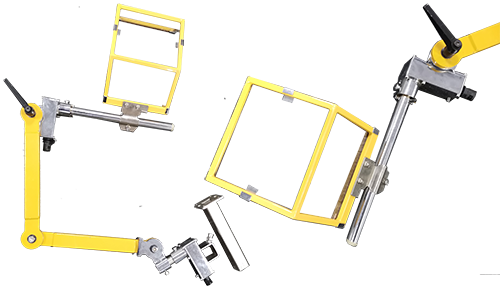

product name | AG61-CG40 | AG61-CG50 | Security door lock | Safety control system |

Dimensions | A:454 B:450 C:500 D:200 | A:504 B552 C:580 D:220 | √ | √ |

Explanation |

Product technical description

· Control of access to the hazardous area The design and positioning of the protective cover of the movable lathe should be such that it can prevent the protective cover from closing when there are people left in the hazardous area during normal operation. If this is not feasible, other measures should be taken to prevent the detection of persons in the danger zone. See GB/T 15706-2012, 6.3.3.2.3. |  |

|

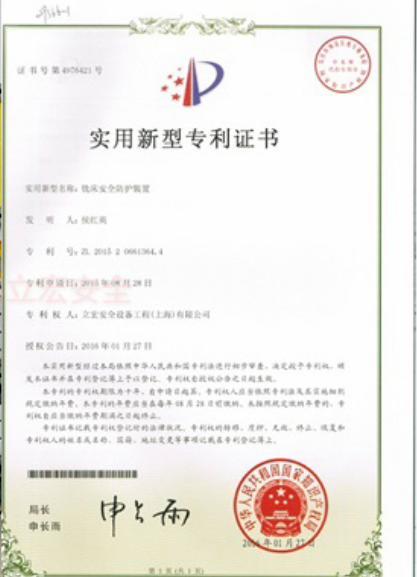

Confirm safety and security through a third-party certification body.

|

Product patent

The design of the drilling machine protective cover should properly consider the operation of the machine for the foreseeable full life cycle and the predictable machine environment Factors, poor consideration can lead to dangerous conditions that hinder the operation of the machine, which in turn leads to the protective cover provided Was artificially abandoned, thereby exposing the operator to greater risks. Foreseeable aspects of existing operating shields All are properly considered in the design stage to ensure that the design and manufacture of the protective cover itself does not create new dangers. |  |

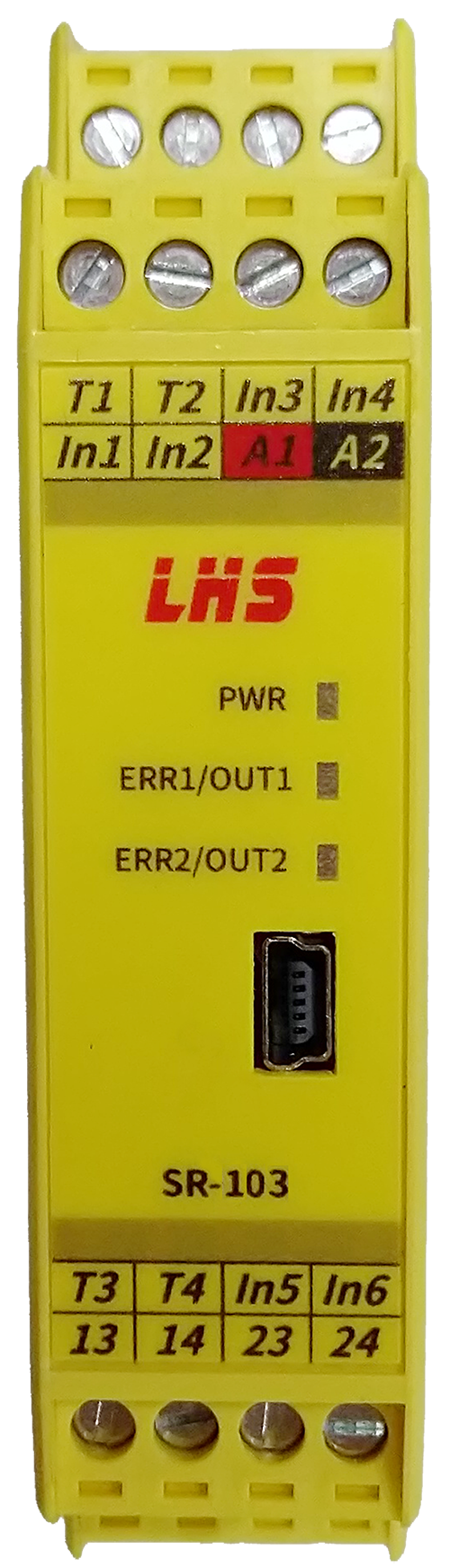

Drilling machine safety circuit module

| SR301 safety relay

Multiple safety product component inputs

ISO 13849-1 Performance Index PLe |  |

SR 103 safety controller

Performance index e corresponding to EN ISO 13849-1 and safety category 4

|

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright © Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing