| SGE 安全触边 |

| ·Shape material EPDM or TPE ·IP65 protection level ·Contact and shape integration ·Internal safety contact strip is included. ·Original cover and wire connector at the end. ·A variety of sizes are available, with a maximum length of 6100mm. |

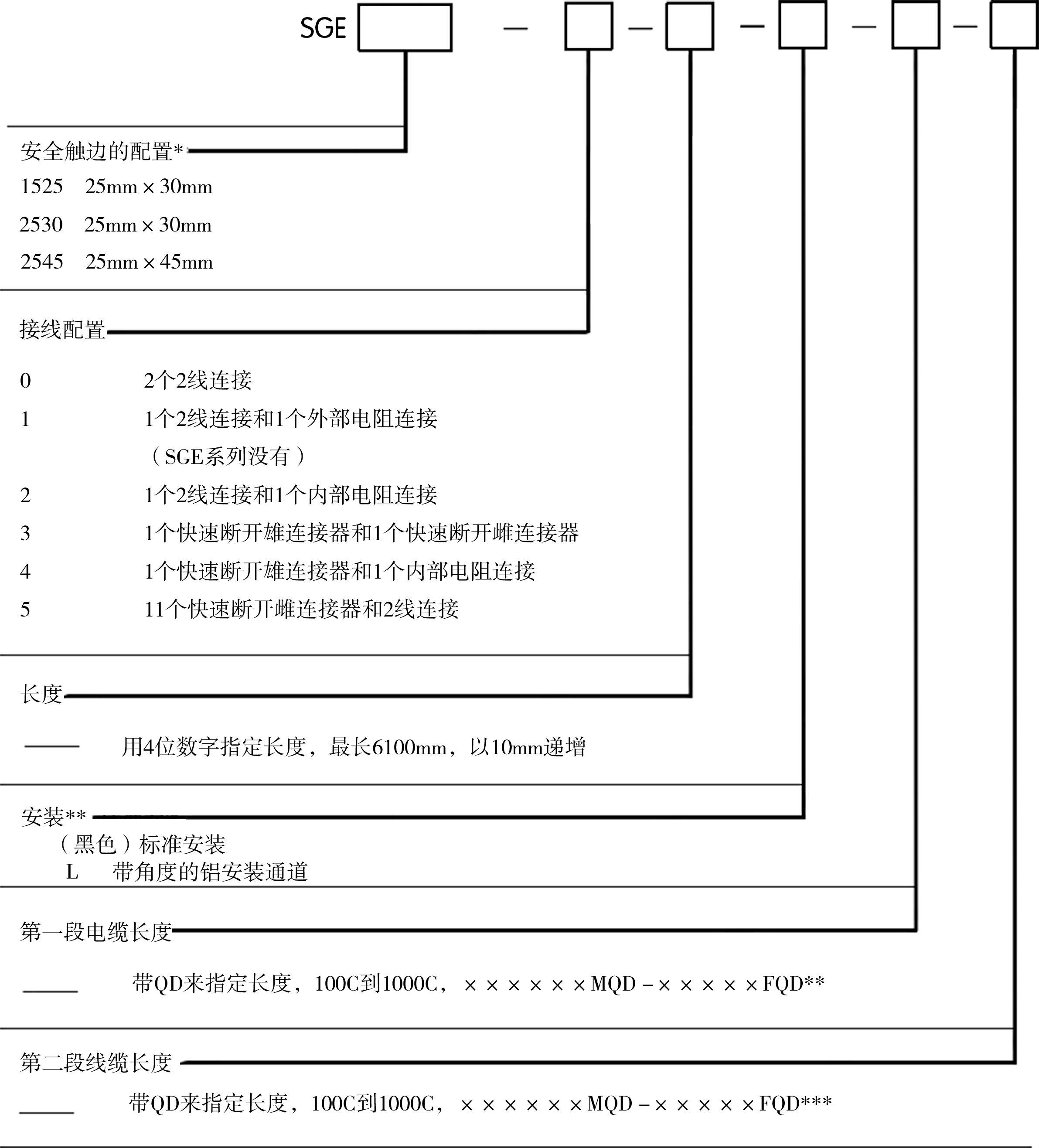

| Product selection |

|  |  |  |

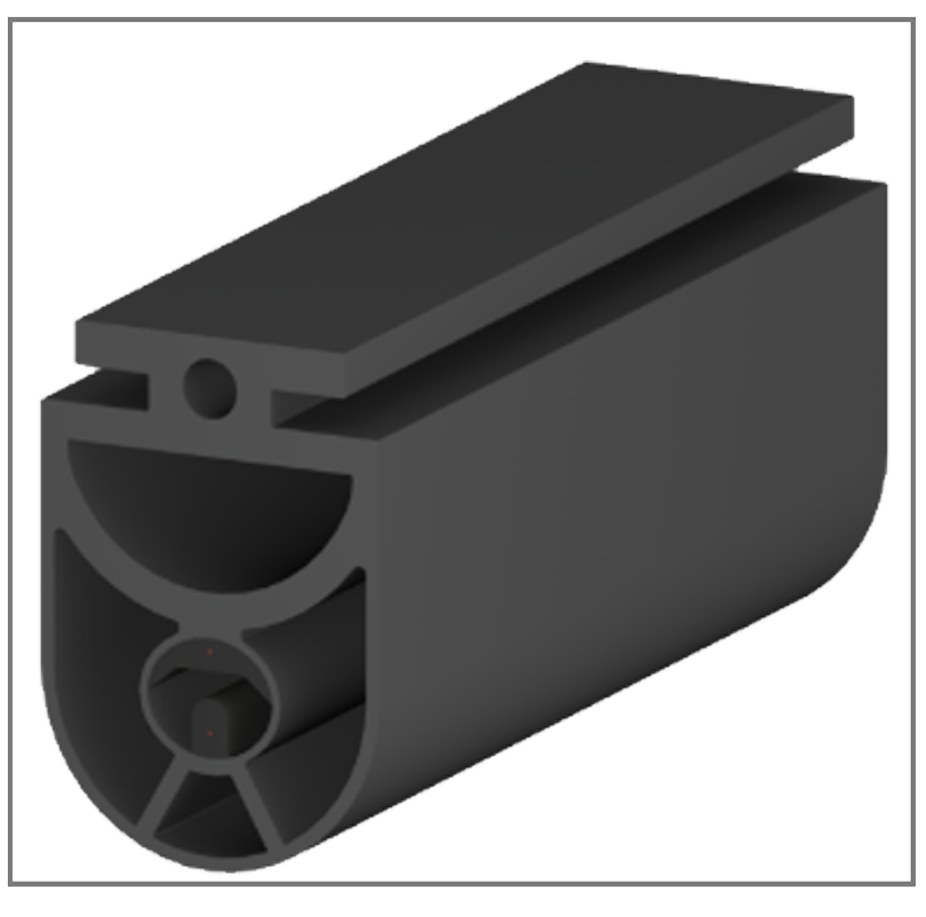

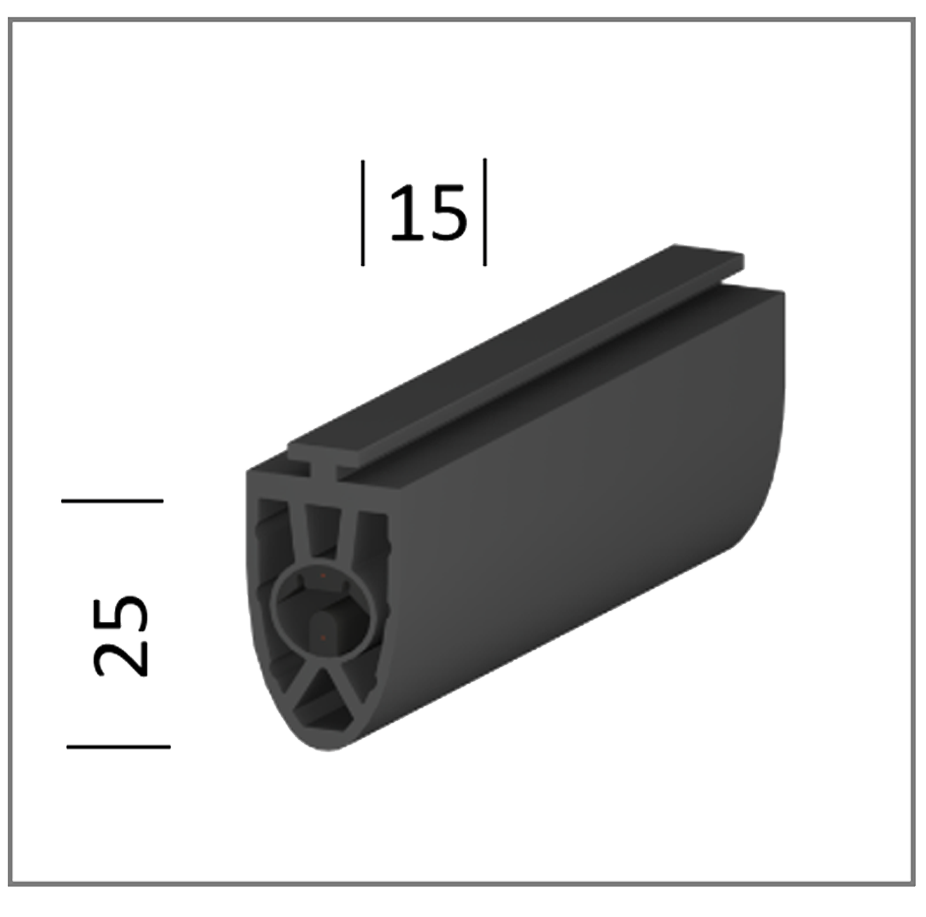

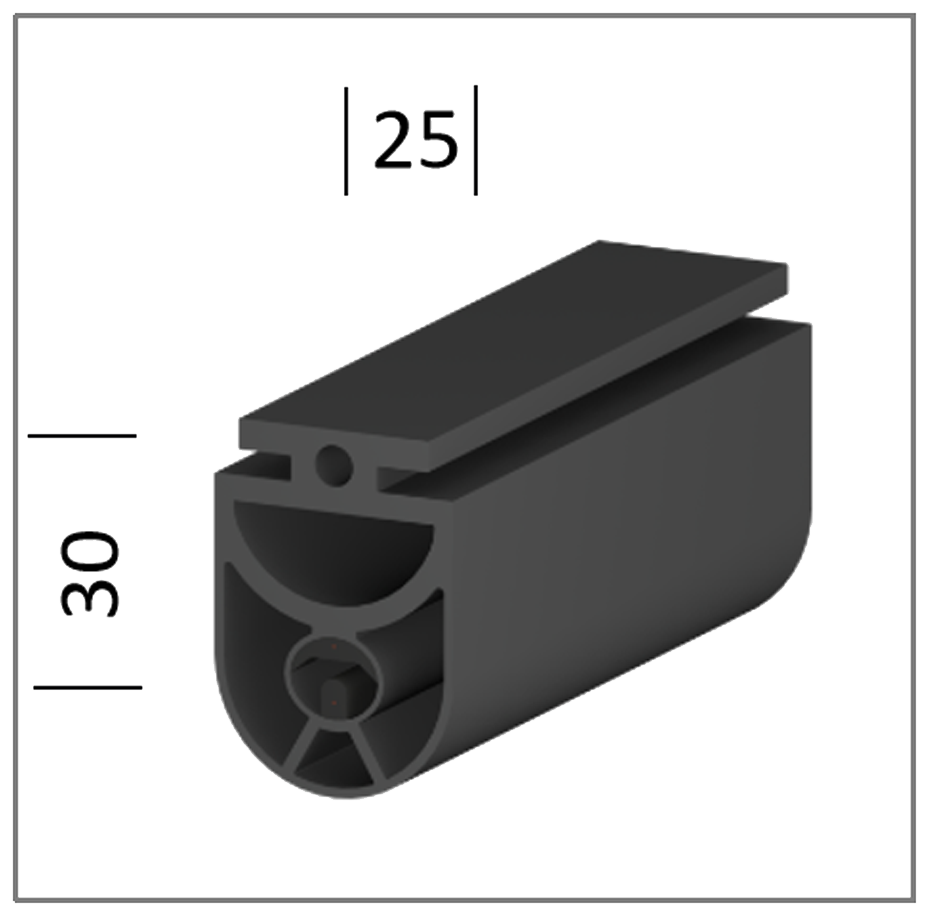

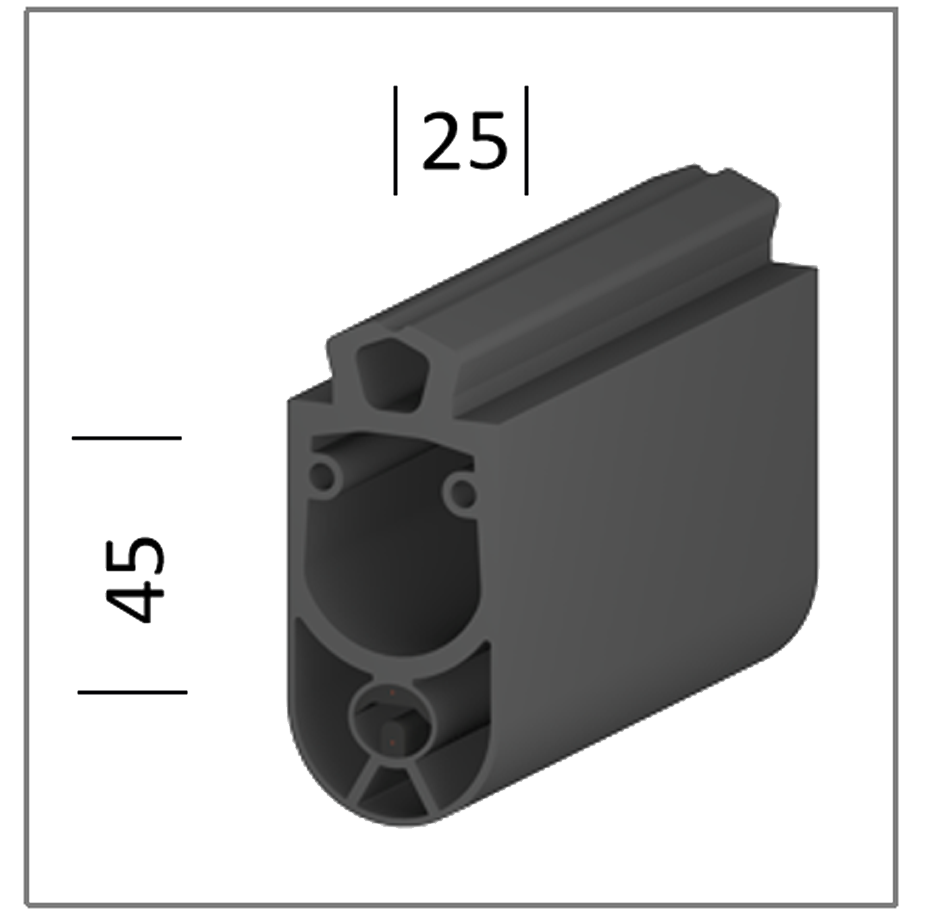

product model | SGE1525TT | SGE2530 | SGE2545 |

material | TPE | EPDM | EPDM |

Material hardness | 65 shore A | 65 shore A | 65 shore A |

product size (width * height) | 15mm*25mm | 25mm*30mm | 25mm*45mm |

the protection grades | IP65(optional IP 68) | IP65(optional IP 68) | IP65(optional IP 68) |

operating temperature | -10~50℃ | -10~50℃ | -10~50℃ |

Capacitance voltage | 24V 100mA | 24V 100mA | 24V 100mA |

safty standard | EN ISO 13856-2 /EN 12978 /EN ISO 13849-1 /UL 325 | ||

![]()

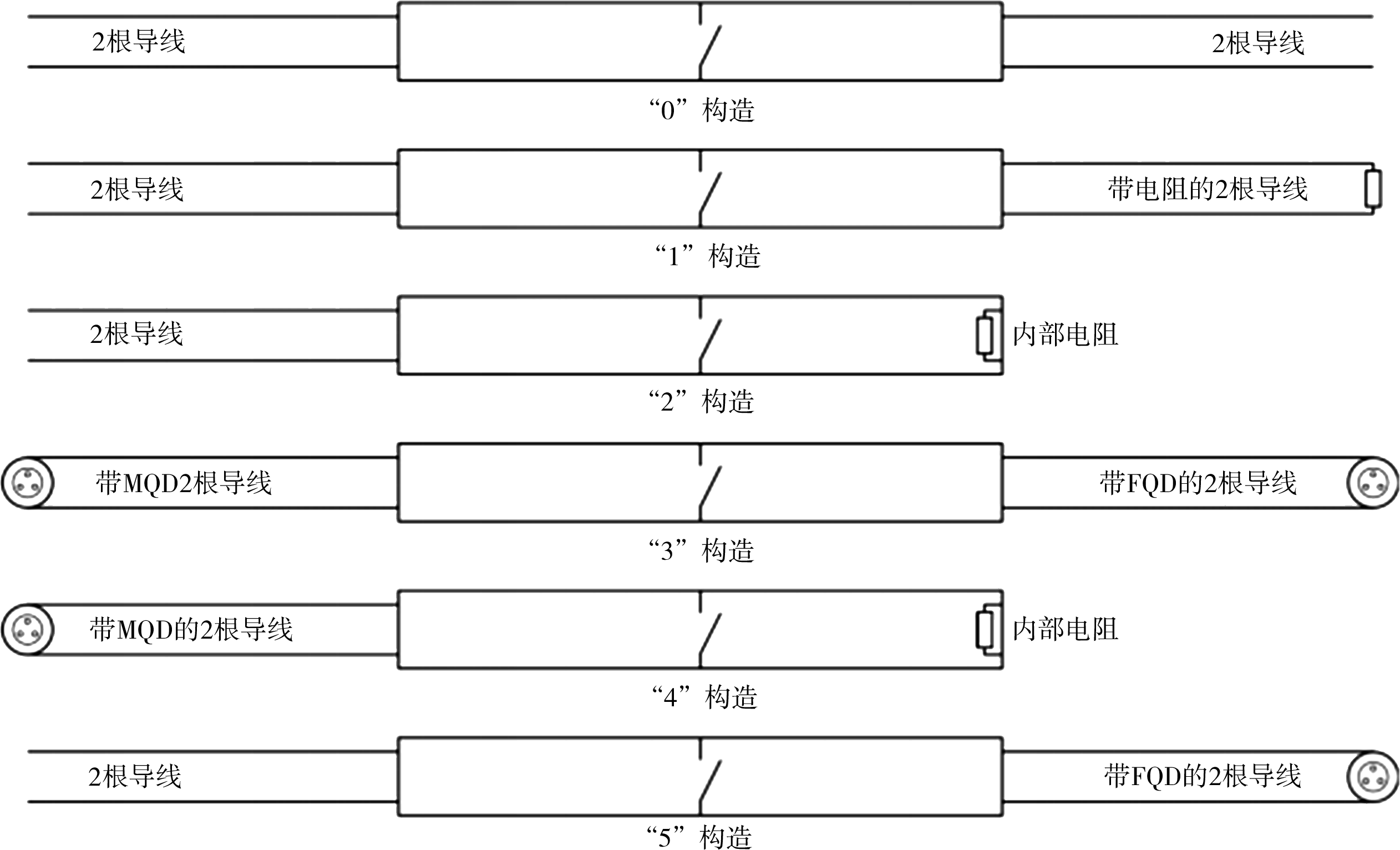

| Ordering information |

Note:

* The standard material for most configurations is EPDM.

(exception: the standard material for SGE1525TT is TPE).

* All shapes of angled aluminum mounting channels can be purchased except SGE1525TT.

* For example, 150C=150mm long cable, 150MQD= 150mm long cable with a quick disconnect male connector at the end.

·Safety contact is installed on the edge of various automatic doors and mobile devices, and other places where impact and extrusion may occur, to protect the safety of people and equipment. ·The special shape (rubber shape) of the safety contact edge can protect the safety contact strip from damage and can realize bending over 90 degrees. ·Contact edges can be connected in series and monitored by the controller. The last safety contact requires a resistor. This design can monitor the short circuit and disconnection of the whole circuit. |

|

| Product characteristics |

material: | EPDM |  |

Material hardness: | 65 Shore A | |

Maximum single length: | 25m | |

the protection grades: | IP65 | |

mechanical force: | 500N | |

Switching period: | 105 | |

Switching angle: | 2*20° | |

starting resistance: | ≤100Ω | |

Electrical capacity: | 24V 100mA | |

operating temperature: | -20~55℃ | |

Maximum operating temperature: | -20~75℃ | |

Maximum length of contact cable: | 100m | |

Maximum number of serial connections: | 10individual connect | |

Motion-free end region: | 20mm | |

cable jumper: | 2 conductor,34mm2 |

| Chemical resistance: |

| trait | TPE (SGE1525TT) | EPDM (SGE2530TT, SGE2545TT) |

Tearing force (resistance) | 3 | 3 |

Final elongatable force | 3 | 3 |

Rebound time at 20℃ | 2 | 2 |

Resistance to permanent deformation | 3-4 | 2 |

wear | 3 | 3 |

Elongation during tearing | 4-5 | 3 |

Low temperature elasticity | 2 | 2 |

High temperature stability | 4 | 2 |

Oxidation stability | 1 | 1 |

UV stability | 1 | 1 |

Resistance to open air/air | 1 | 1 |

fire resistance | 6 | 6 |

Gas permeability | 3 | 4 |

•Key: •1 = Very good; 6= insufficient •Epdm ethylene and propylene rubber: good •Ozone and corrosion resistance, especially for aggressive chemicals. •Tpe thermoplastic elastomer | ||

| trait | TPE (SGE1525TT) | EPDM (SGE2530TT, SGE2545TT) |

resistivity against water | 1 | 1-2 |

Dilution acid | 1 | 2 |

diluent | 1 | 2 |

Non-oxidizing acid | 2 | 2 |

Oxidized acid | 2 | 4 |

ASTM油#3 | 2 | 6 |

vegetable oil | 1-2 | 5 |

organic solvent | 2-3 | 2 |

Ketone solvent (containing oxygen) | 2-3 | 3 |

hydrocarbon | 2-3 | 5-6 |

alcohol | 1 | 1 |

| • Key: • 1= invalid, persistent contact • 2= hardly effective, little contact. • 3= general effect, general contact • 4= significant effect, reducing contact • 5= Severe effect, very brief contact. • 6= Extreme effect, avoid contact. | ||

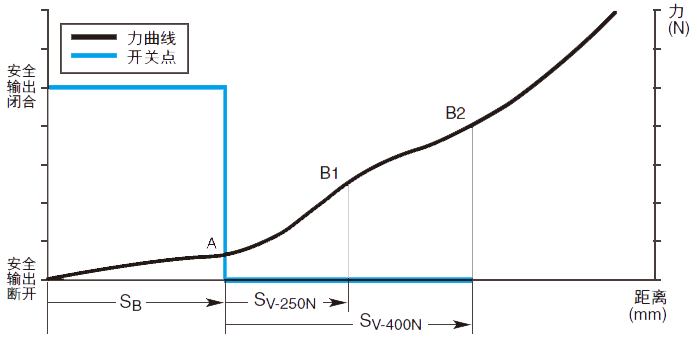

| Characteristic data: |

![]()

![]()

| Characteristic data: |

Take SGE2530 as an example (characteristic value at test speed v=10mm/s) Test temperature+20c |

|

| SGE1525TT(Characteristic value at test speed V=10mm/s) | SGE1525TT(Characteristic value at test speed V=100mm/s) | ||

| Test temperature | +20°C | Test temperature | +20°C |

| Trigger force FA(N) | 42 | Trigger force FA(N) | 43 |

| Trigger distance SB(mm) | 2.6 | Trigger distance SB(mm) | 6.4 |

Overtravel distance SV (mm) (at 250 n) | 8.1 | Overtravel distance SV (mm) (at 250 n) | 7.7 |

Overtravel distance SV (mm) (at 400 n) | 9.5 | Overtravel distance SV (mm) (at 400 n) | 8.6 |

| Note: According to the test of EN ISO 13856-2, the sample is 80mm round and the trigger point is C3. | Note: According to the test of EN ISO 13856-2, the sample is 80mm round and the trigger point is C3. | ||

| SGE2530(Characteristic value at test speed V=10mm/s) | SGE2530(Characteristic value at test speed V=100mm/s) | ||

| Test temperature | +20°C | Test temperature | +20°C |

| Trigger force FA(N) | 57 | Trigger force FA(N) | 63 |

| Trigger distance SB(mm) | 3.9 | Trigger distance SB(mm) | 4.4 |

Overtravel distance SV (mm) (at 250 n) | 2.3 | Overtravel distance SV (mm) (at 250 n) | 2.7 |

Overtravel distance SV (mm) (at 400 n) | 6.7 | Overtravel distance SV (mm) (at 400 n) | 7.2 |

Note: According to the test of EN ISO 13856-2, the sample is 80mm round and the trigger point is C3. | Note: According to the test of EN ISO 13856-2, the sample is 80mm round and the trigger point is C3. | ||

| SGE2545(Characteristic value at test speed V=10mm/s) | SGE2545(Characteristic value at test speed V=100mm/s) | ||

Test temperature | +20°C | Test temperature | +20°C |

Trigger force FA(N) | 68 | Trigger force FA(N) | 83 |

Trigger distance SB(mm) | 7.4 | Trigger distance SB(mm) | 7.8 |

Overtravel distance SV (mm) (at 250 n) | 15.8 | Overtravel distance SV (mm) (at 250 n) | 15.2 |

Overtravel distance SV (mm) (at 400 n) | 18.3 | Overtravel distance SV (mm) (at 400 n) | 17.7 |

Note: According to the test of EN ISO 13856-2, the sample is 80mm round and the trigger point is C3. | Note: According to the test of EN ISO 13856-2, the sample is 80mm round and the trigger point is C3. | ||

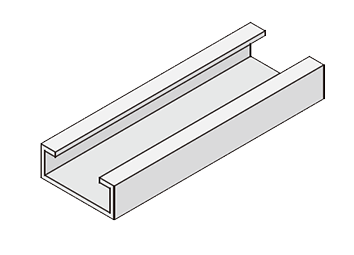

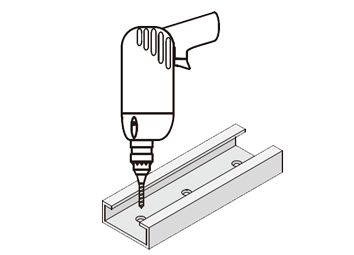

| Installation: |

1. In order to facilitate the installation of the safety contact edge, the installation base must be fixed on a flat surface. If the safety contact edge needs to be installed in a certain arc, the bending radius shall not be less than the specified minimum value. | 5. The connecting wire and the cable end with terminal resistance must be put into the installation base. |

| |

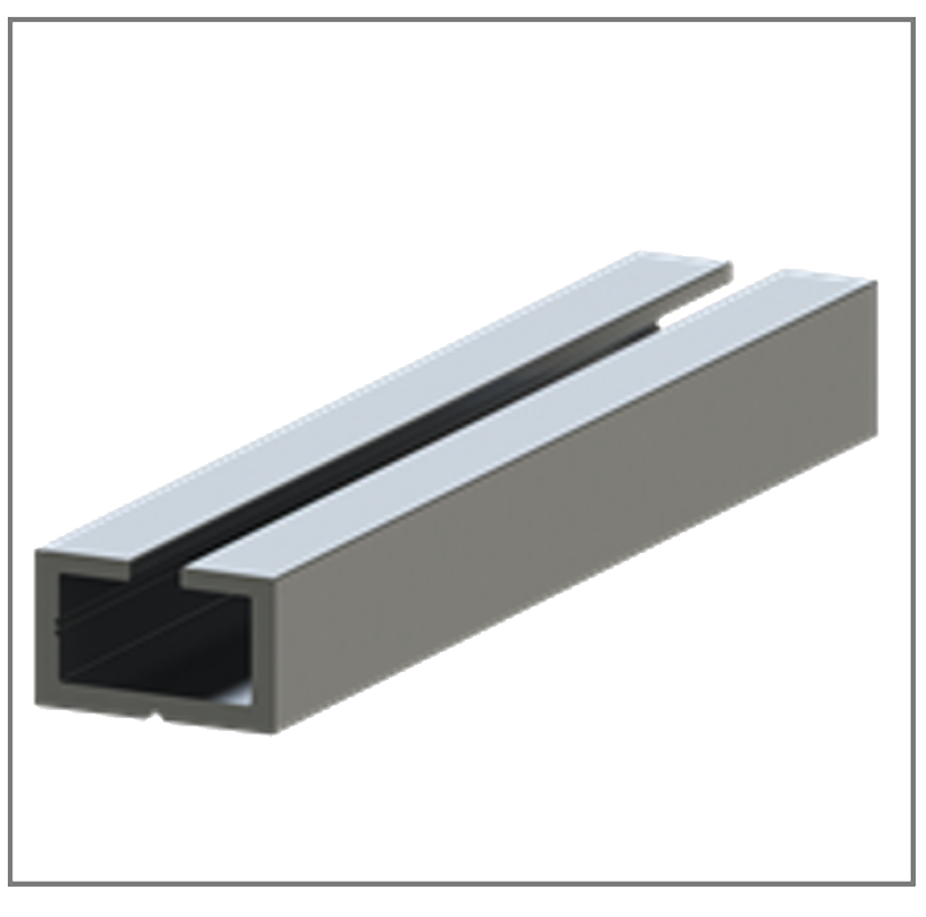

2. The installation base must be fixed with countersunk head screws or rivets, with a diameter of 4 mm.. Nail holes are 4.5mm, which must be evenly distributed on the whole length of the installation base, and the hole spacing should not exceed 300 mm. The countersunk part must be machined according to the screw size. SGE-2530/2545 (L-shaped) | 6. To make the safety contact easier to install, soapy water should be sprayed on the installation base and the safety contact. After the soapy water evaporates, the safety contact edge can be firmly fixed on the aluminum base. In order to avoid sliding after safe contact, talcum powder, oil and other lubricants with lasting effect shall not be used. |

|  |

When using SGE-1525TT, drill a guide hole in the groove to ensure that the head of countersunk head screw can pass through (about 8mm). | 8. For the safety contact edge with T-shaped base (SGE-1525TT/-2530/-2545), it should be inserted from the side along the groove of the mounting base. |

|  |

3. Flat head or round head screws cannot be used, otherwise the connecting wires in the mounting base will be damaged. | To use other fastening methods, it must be agreed with the manufacturer in advance. |

| |

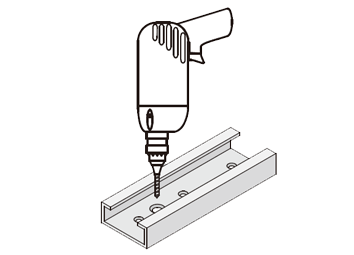

4. In order to make the connecting wire pass through the base, an 8mm hole must be drilled at a proper position. Carefully remove the burrs on both sides. | |

|

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright © Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing