| Safety light curtain for single/two-way feeding and discharging detection ·Cross-detection feeding and discharging mode ·Bidirectional detection feeding and discharging mode ·Protection height from 120-1960 mm. ·The default detection distance of LS4T series is 0-10M, and other detection distances can be customized. ·Integrated a variety of intelligent functions. ·Integrated manual or automatic reset ·External relay feedback input (EDM) |

| ▊ | Product selection |

Detection accuracy 45mm series | ||||||

specifications and models | Beam number | Optical axis spacing (mm) | Protection height (mm) | Product length (mm) | complete built unitMTTFd(year) | complete built unit MTTF(year) |

LS4T-45-0140 | 4 | 40 | 120 | 140 | 566.18 | 109.27 |

LS4T-45-0220 | 6 | 40 | 200 | 220 | 532.86 | 101.24 |

LS4T-45-0300 | 8 | 40 | 280 | 300 | 503.25 | 94.31 |

LS4T-45-0380 | 10 | 40 | 360 | 380 | 476.76 | 88.27 |

LS4T-45-0460 | 12 | 40 | 440 | 460 | 452.92 | 82.95 |

LS4T-45-0540 | 14 | 40 | 520 | 540 | 431.35 | 78.24 |

LS4T-45-0620 | 16 | 40 | 600 | 620 | 411.74 | 74.04 |

LS4T-45-0700 | 18 | 40 | 680 | 700 | 393.83 | 70.26 |

LS4T-45-0780 | 20 | 40 | 760 | 780 | 377.42 | 66.85 |

LS4T-45-0860 | 22 | 40 | 840 | 860 | 362.32 | 63.76 |

LS4T-45-0940 | 24 | 40 | 920 | 940 | 348.38 | 60.94 |

LS4T-45-1020 | 26 | 40 | 1000 | 1020 | 335.48 | 58.36 |

LS4T-45-1100 | 28 | 40 | 1080 | 1100 | 323.50 | 55.99 |

LS4T-45-1180 | 30 | 40 | 1160 | 1180 | 312.34 | 53.80 |

LS4T-45-1260 | 32 | 40 | 1240 | 1260 | 301.93 | 51.78 |

LS4T-45-1340 | 34 | 40 | 1320 | 1340 | 292.19 | 49.90 |

LS4T-45-1420 | 36 | 40 | 1400 | 1420 | 283.05 | 48.16 |

LS4T-45-1500 | 38 | 40 | 1480 | 1500 | 274.48 | 46.53 |

LS4T-45-1580 | 40 | 40 | 1560 | 1580 | 266.40 | 45.01 |

LS4T-45-1660 | 42 | 40 | 1640 | 1660 | 258.79 | 43.59 |

LS4T-45-1740 | 44 | 40 | 1720 | 1740 | 251.60 | 42.25 |

LS4T-45-1820 | 46 | 40 | 1800 | 1820 | 244.80 | 41.00 |

LS4T-45-1900 | 48 | 40 | 1880 | 1900 | 238.36 | 39.81 |

LS4T-45-1980 | 50 | 40 | 1960 | 1980 | 232.24 | 38.69 |

1. The above models are the default detection distance. Type A: 0-10m, and (-□) can be added after the models, and the detection distance can be customized. Type B: 0-16m, Type C: 0-5m, Type D: 0-40m and Type E: 0-70m. 2. Other lengths are subject to customization. | ||||||

| ▊ | 2Safety combination of point-crossing feeding and discharging detection |

| Safety light curtain for cross feeding and discharging detection ·Why do you need Muting? It can prevent people from entering the dangerous operation area of the machine through the cargo opening, thus causing mechanical injury, and the cargo can pass smoothly without stopping, that is, it will not affect the production efficiency. ·Reference standards IEC 62046, ISO13849 and IEC61496.. Product composition: ·2Group sensor (cross sides) ·Safety light curtain (installed vertically in the middle) ·By sequentially detect that entrance and exit of pallet materials or AGV trolley Please download the corresponding program matching Muting program. |

| ▊ | 4Safety combination of point bidirectional parallel feeding and discharging detection |

| Two-way parallel feeding and discharging detection safety light curtain ·Why do you need Muting? It can prevent people from entering the dangerous operation area of the machine through the cargo opening, thus causing mechanical injury, and the cargo can pass smoothly without stopping, that is, it will not affect the production efficiency. ·Reference standards IEC 62046, ISO13849 and IEC61496. Product composition: ·4Group sensor (horizontal sides) ·Safety light curtain (installed vertically in the middle) ·By sequentially detect that entrance and exit of pallet materials or AGV trolley Please download the corresponding program matching Muting program. |

| ▊ | Product components |

· Safety grating (the height of the main grating is confirmed according to the site) · 2Group detection sensor (cross-mounted) is installed at the lower part of aluminum material to prevent collision. · TT-shaped fixing bracket · 5M cable |

| ▊ | Industrial application |

· Automated production line · Palletizer industry · Food packaging line industry · Warehousing industry · AGV inlet and outlet |

| ▊ | Wiring instructions |

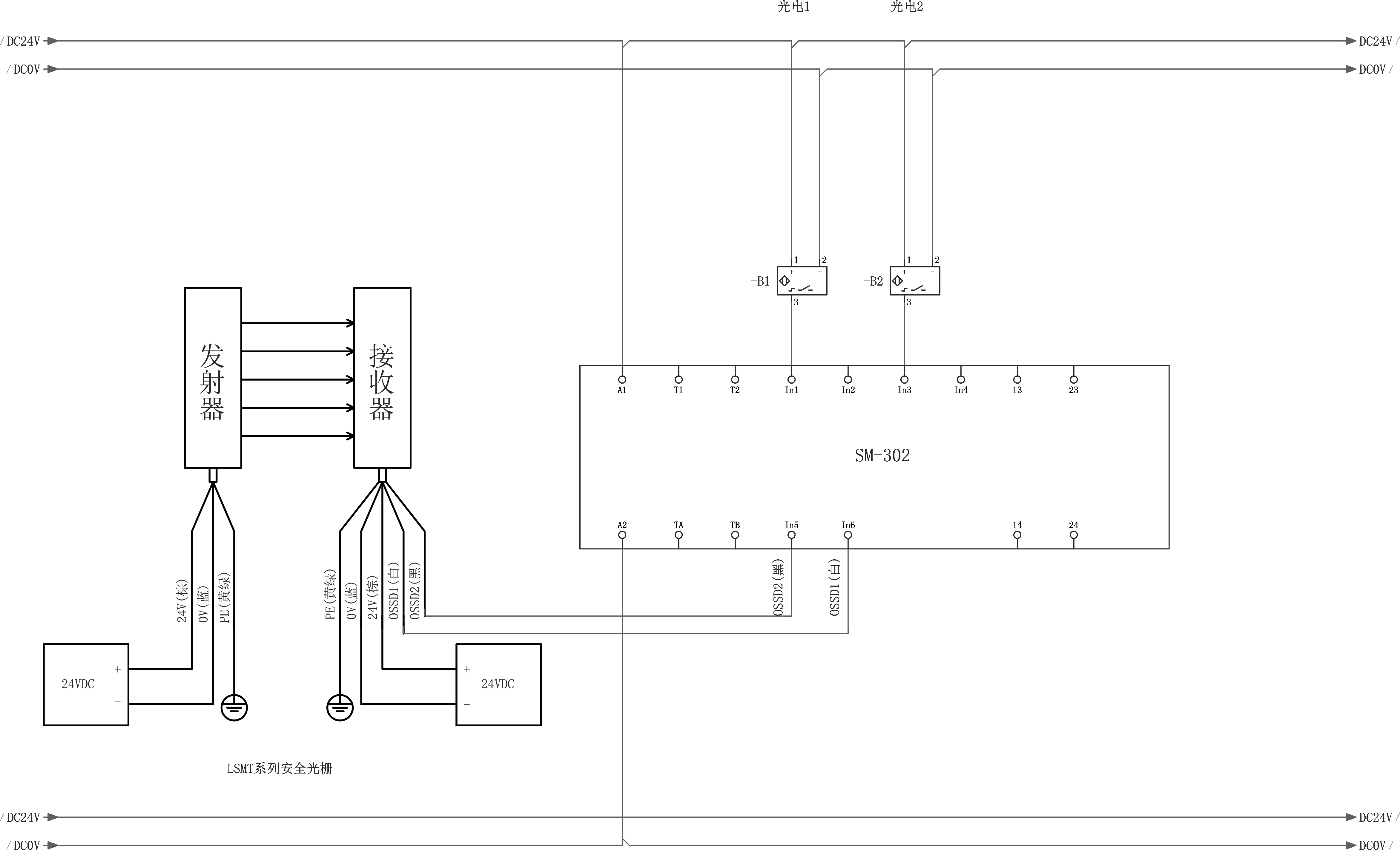

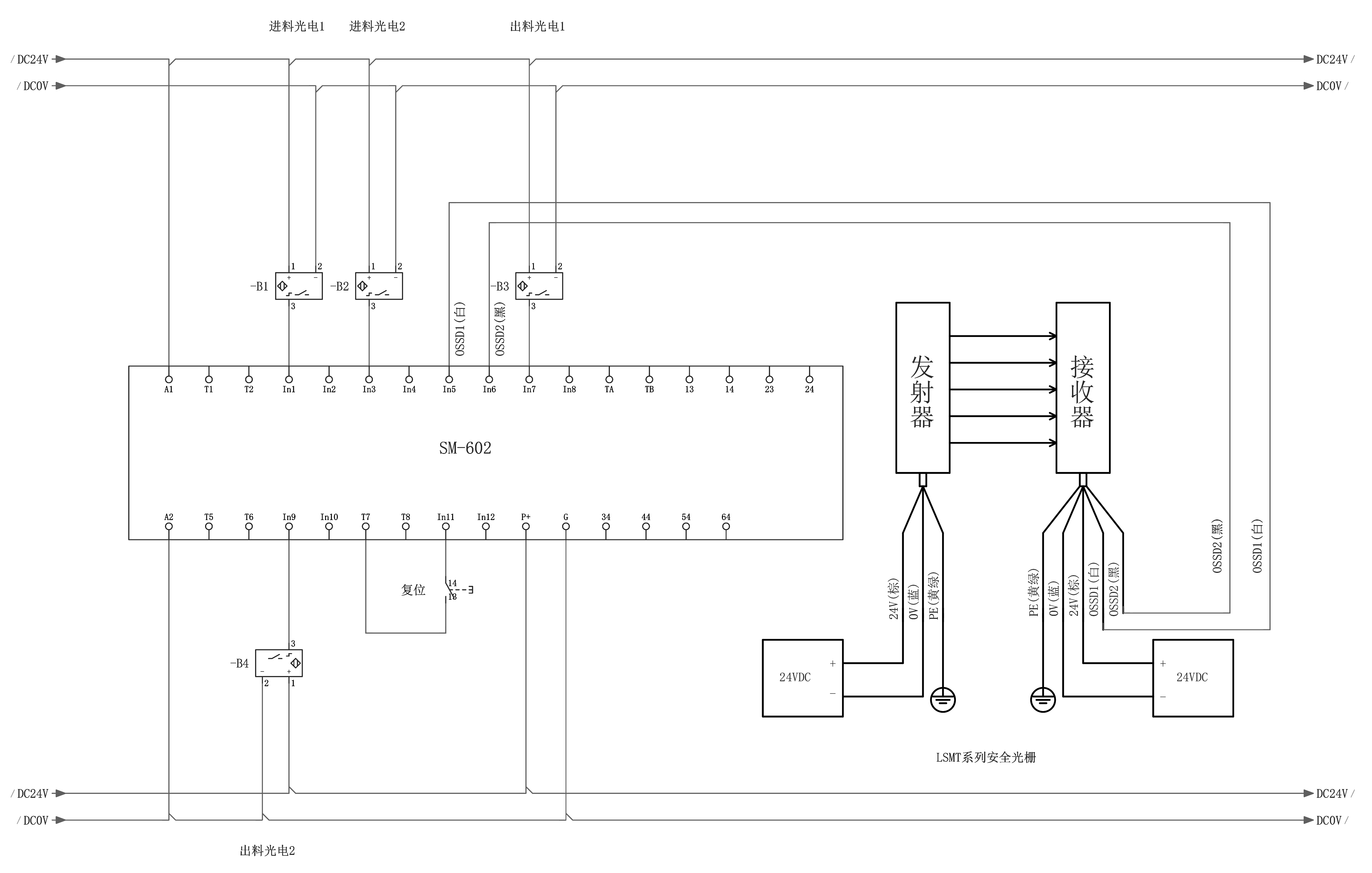

Muting wiring diagram (schematic diagram of 302 cross feeding and discharging detection) | Muting wiring diagram (602 bidirectional parallel feeding and discharging detection diagram) |

|  |

| ▊ | technical parameter |

executive standard | ||||

European Standards | EN 61496-1、2:2020、EN 61508-1~4:2020、EN ISO 13849-1、2:2023 | |||

international standard | IEC 61496-1、2:2020、IEC61508-1~4:2010、ISO 13849-1、2:2023 | |||

Chinese standard | GB 4584 | |||

Security category | ||||

security level/phase | Type4、SIL3、Category4、PLe | |||

MTTFd | 157~557year No, please check the model details. | |||

Optical parameters | ||||

Emitting light source | Infrared LED (central wavelength 850nm) | |||

Optical axis spacing | 40mm | |||

Detection accuracy | 45mm | |||

Protective height | (Number of beams -1)* Optical axis spacing (unit mm) | |||

Detection distance | Type A: 0 ~ 10m, type B: 0 ~ 16m, type C: 0 ~ 5m, type D: 0 ~ 40m and type E: 0 ~ 70m. | |||

environmental parameter | ||||

ambient temperature | Working temperature | -10℃~55℃(Smooth surface without frost and dew condensation) | ||

storage temperature | -40℃~70℃ | |||

ambient humidity | Working humidity | 35%RH~85%RH | ||

storage temperature | 35%RH~95%RH | |||

Anti-light interference | filament lamp | 3000Lux | ||

fluorescent lamp | 3000Lux | |||

sunlight | 10000Lux | |||

Anti-vibration ability | The frequency is 10Hz-55Hz, the amplitude is 0.35±0.05mm, and the frequency is 20 times in X, Y and Z directions respectively. | |||

Impact resistance | The acceleration is 10g, the pulse duration is 16ms, and 1000 times in X, Y and Z directions respectively. | |||

sectional dimension | 34×28mm | |||

电气特性 | ||||

operating voltage | 24V DC±20% | |||

operational current | Transmitter: < 200mA | Receiver: < 200mA (no load) | ||

Response time | 4ms-18ms(Increase or decrease with the number of beams) | |||

Safe output (OSSD) | PNP | PNP transistor output ×2; In the ON state, the load current is ≤100mA and the output voltage is ≥Vcc-2V; In the OFF state, the leakage current is ≤1mA, and the residual voltage is ≤ 1V (excluding the influence of wire extension). | ||

NPN | When the NPN transistor outputs ×2, the load current is ≤100mA and the output voltage is ≤2V; In the OFF state, the leakage current is ≤1mA and the residual voltage is ≤2V (excluding the influence of wire extension). | |||

start time | < 3s | |||

Detection function | Power-on self-inspection, real-time self-inspection during work. | |||

protective circuit | Overvoltage and overcurrent protection, output short circuit protection | |||

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright © Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing