As the most important part of safety loop, safety controller/safety PLC has been recognized by more and more people, but in the process of use, there are still many users who are confused about the differences between safety relay and ordinary relay, so I would like to share them with you here. As we all know, we must remember three words in the concept of safety design:

(1) Redundancy (2) Difference (3) Self-detection |

How to construct the safety loop with the reliability above PLd, the safety controller must become an important link. The safety loop consists of safety input, safety control and safety output subsystems, and the safety control "including safety relay, safety controller, safety PLC, etc." realizes the safety control function. Designers match different safety controllers to achieve the reliability level of the safety loop according to the number of products at the input end.

| ▊ | SM-602 programmable safety controller |

| • Is a configurable safety controller, which supports the input of various safety product components. • Maximum support for 6 sets of dual-loop inputs. • 2-way safety relay output • 4-channel semiconductor safety output, expandable output module • Modbus protocol communicationInput and output fault indicator light • Safety certification: PL e, Cat: 4 |

| ▊ | Product selection |

product name | Type number | Safe input | Output | Brand |

Safety controller | SM-602 | 6CH | 2NO+4SO | LHS |

| explain | Up to 6 sets of dual-channel safety products can be entered. Safety grating, emergency stop, safety door lock, reset, etc. Official website programming software download connection: http://lhsafety.com.cn/showinfo-257-118-0.html | |||

| ▊ | safety performance |

• Performance level (PL): PL e • Security category (Cat.): Cat.4 • Mission time (TM): 20 years • Diagnostic coverage (DC/DC avg): 99% • Safety Integrity Level (SIL): SIL3 • Hardware Fault Margin (HFT): 1 • Safe Failure Score (SFF): 99% • Probability of dangerous failure (PFH d): 1.78E-9/h • Stop Category: 0/1 | Complies with standard EN ISO13849 Complies with standard EN ISO13849 Complies with standard EN ISO13849 Complies with standard EN ISO13849 Conforms to standards IEC61508, IEC62061 Conforms to standards IEC61508, IEC62061 Conforms to standards IEC61508, IEC62061 Conforms to standards IEC61508, IEC62061 Complies with standard EN 60204-1 |

▊Main technical parameters

Power supply characteristics | ·Power supply voltage: 24VDC ·Voltage range: 20~30VDC ·Current loss: ≤110mA(24VDC) |

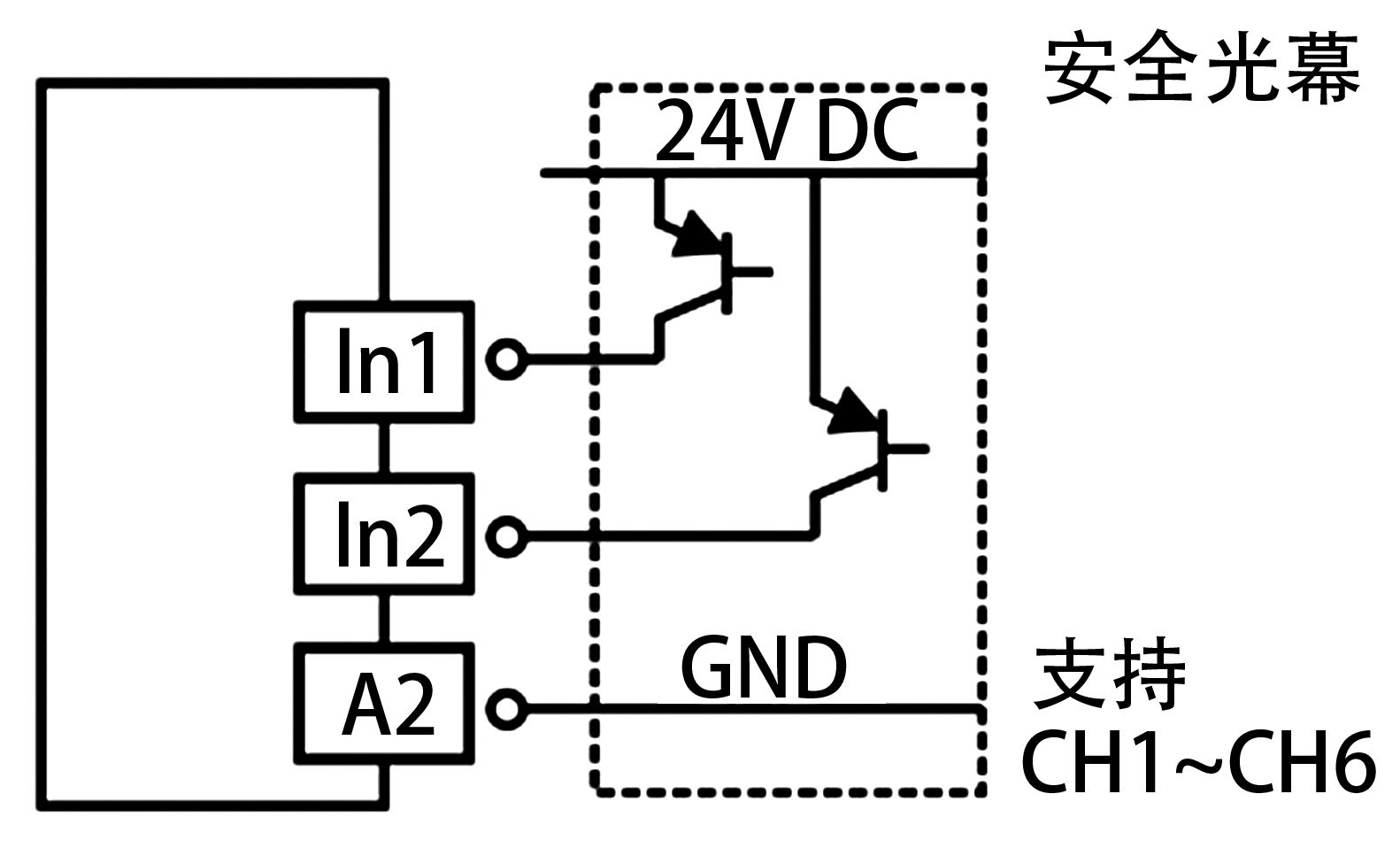

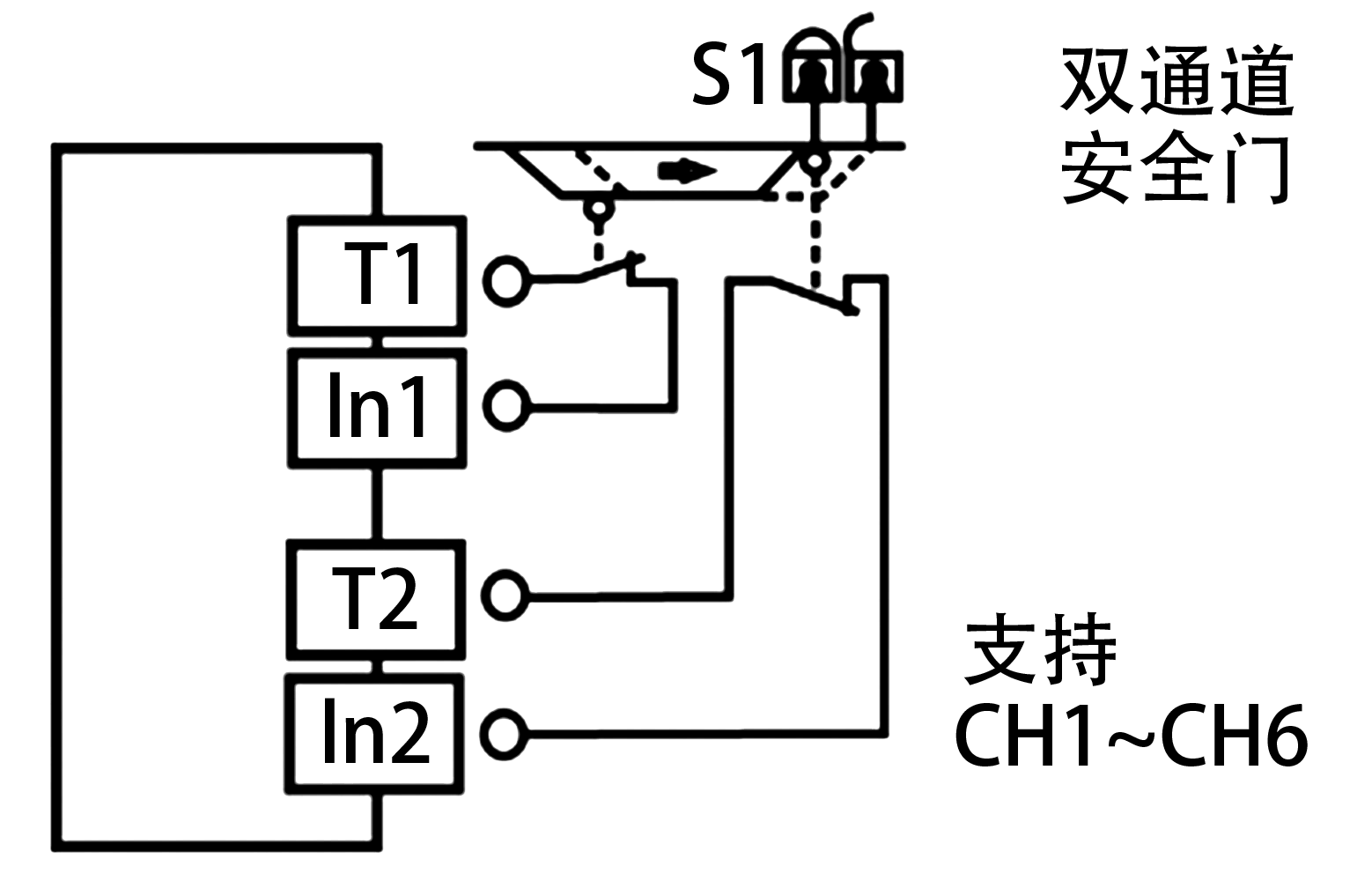

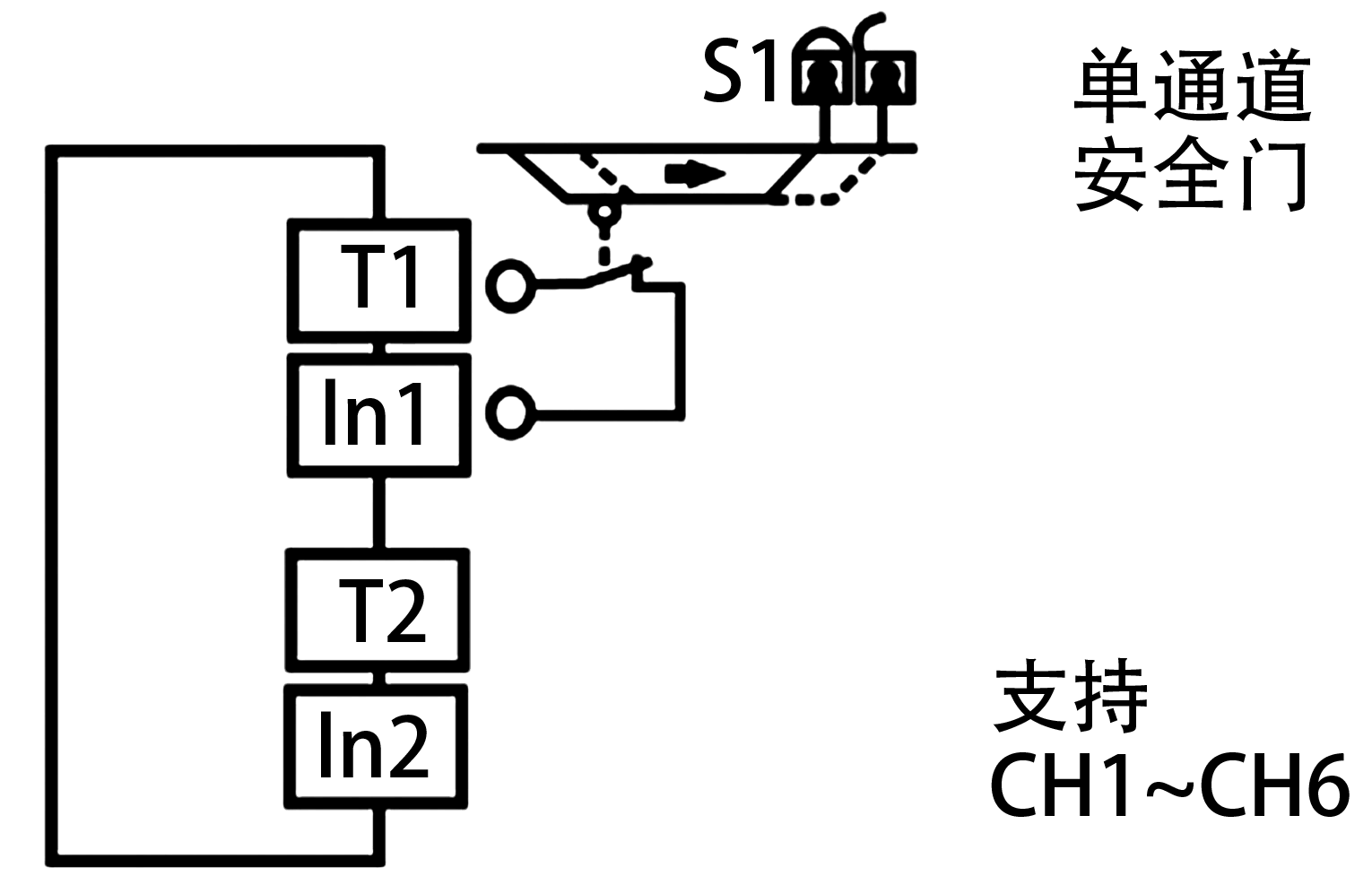

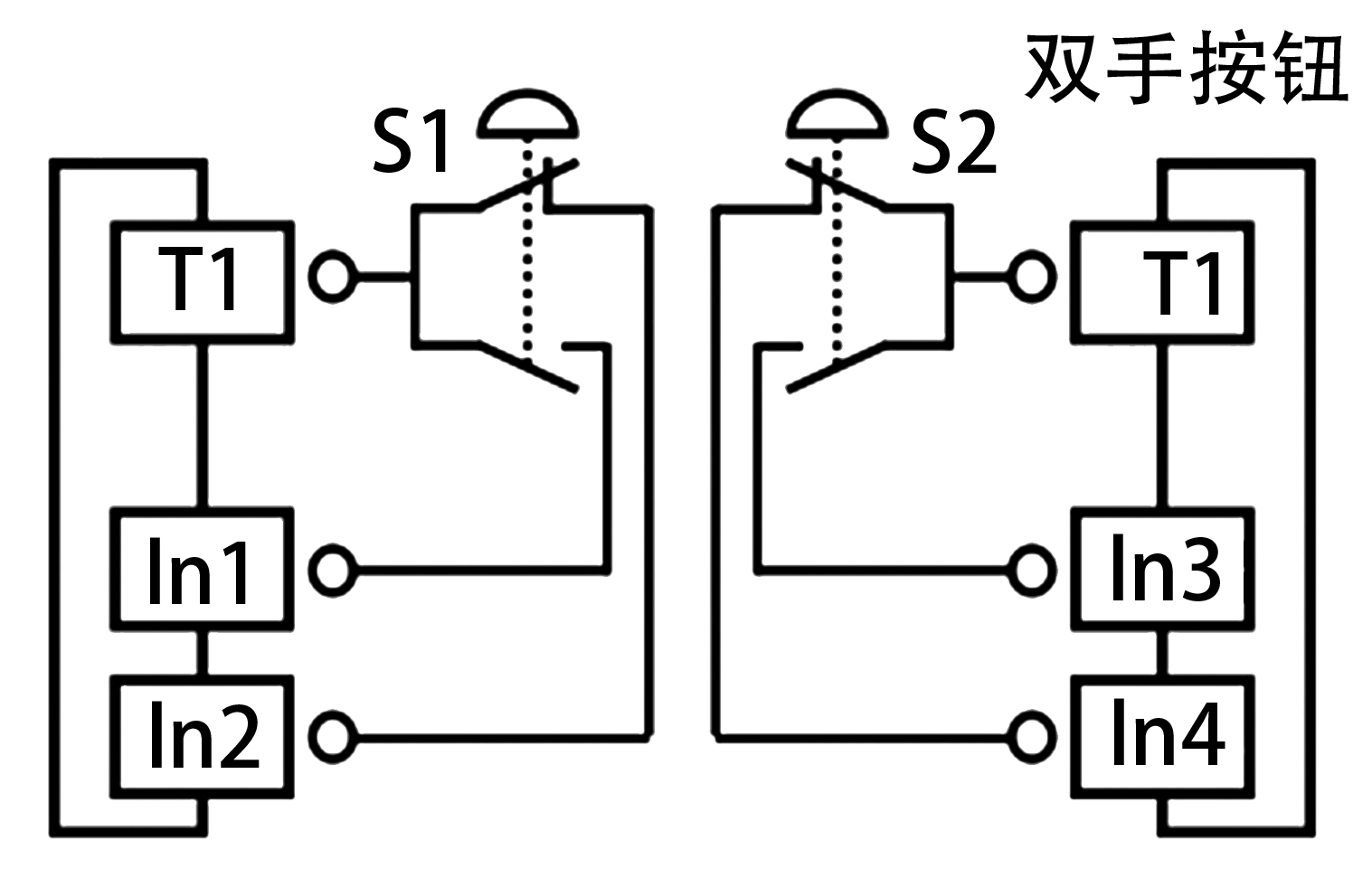

Input characteristics | ·Input current: ≤10mA(24VDC) ·Conductor resistance: ≤15Ω ·Input equipment: emergency stop button, safety door, two-hand button safety light curtain, magnetic safety switch, etc. ·Input channel: 6 |

Relay output characteristics | ·Number of contacts: 2NO (safety output) ·Contact material: AgSnO2 ·Contact fuse protection: 10A is fast, 6A is slow. ·Switching capacity: 5A/230VAC;; 5A/24VDC |

| Semiconductor output characteristics | ·Number of contacts: 4SO (safety output) ·Contact fuse protection: 10A is fast, 6A is slow. ·Switching capacity: 2A/24VDC |

Time characteristic | ·Suction buffer time: ≤100ms ·Release buffer time: ≤30ms ·Recovery time: Emergency stop operation: ≤30ms Power failure: ≤1000ms ·Recovery time: Emergency stop operation: ≤30ms Power failure: ≤100ms ·Short-term power interruption: 20ms |

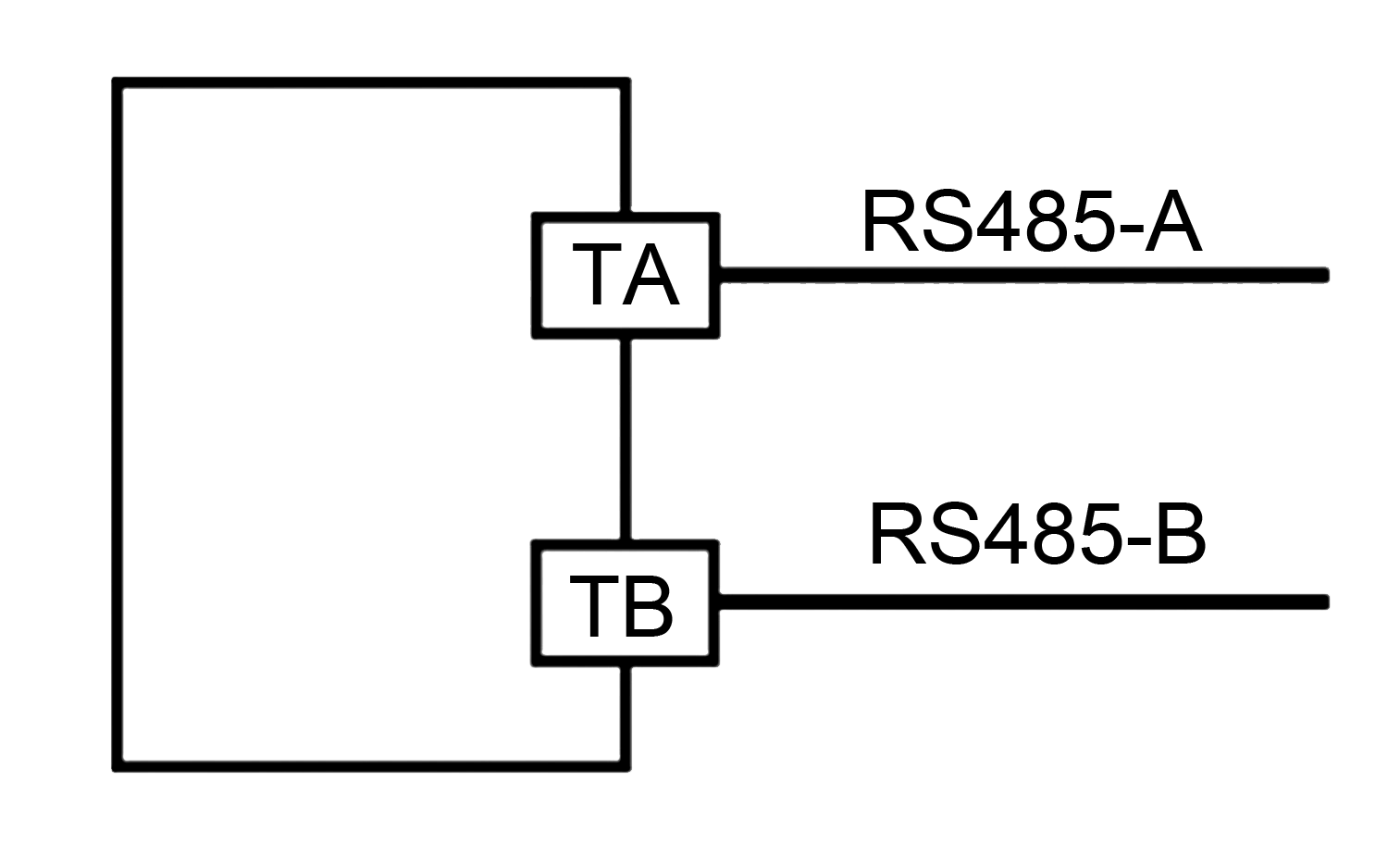

Communication characteristics | ·Baud rate: 38.4kbps (fixed) ·Communication length: ≤1000m ·Networking capacity: ≤10 units |

| ▊ | Environmental characteristic parameters |

·Electromagnetic compatibility: comply with EN60947, EN61000-6-2 and EN61000-6-4. ·Vibration frequency: 10Hz~55Hz ·Vibration amplitude: 0.35mm ·Service temperature: -20℃~+60℃ ·Storage temperature: -40℃~+85℃ ·Relative humidity: 10%~90% ·Overvoltage grade: Ⅲ ·Pollution level: 2 ·Altitude: ≤2000m ·Rated isolation voltage: 250VAC. ·Rated impulse voltage: 6000V(1.2/50us) ·Insulation strength: 1500VAC, 1min. ·Electrical clearance and creepage distance: in accordance with EN60947-1. |  |

| ▊ | Functional application parameters |

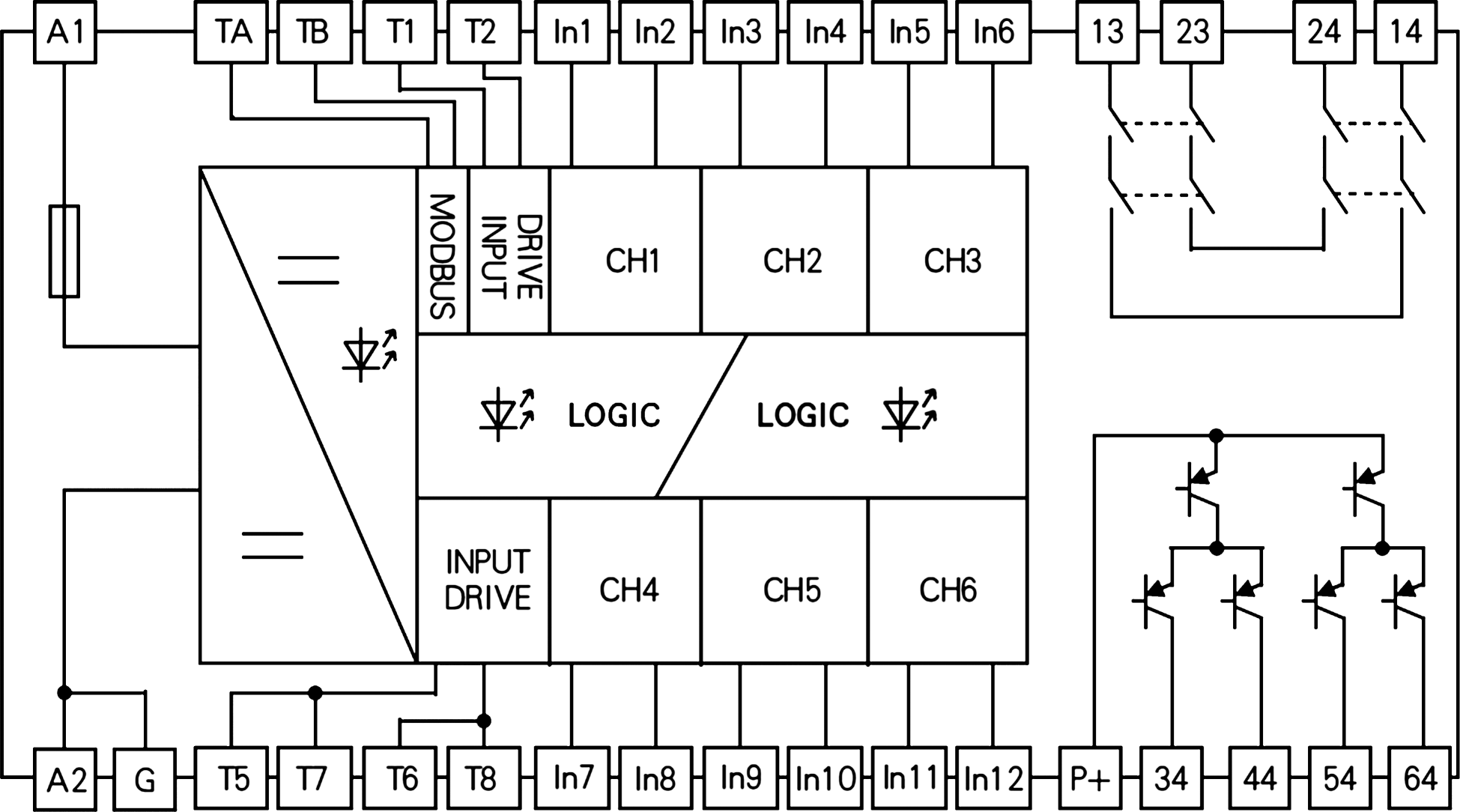

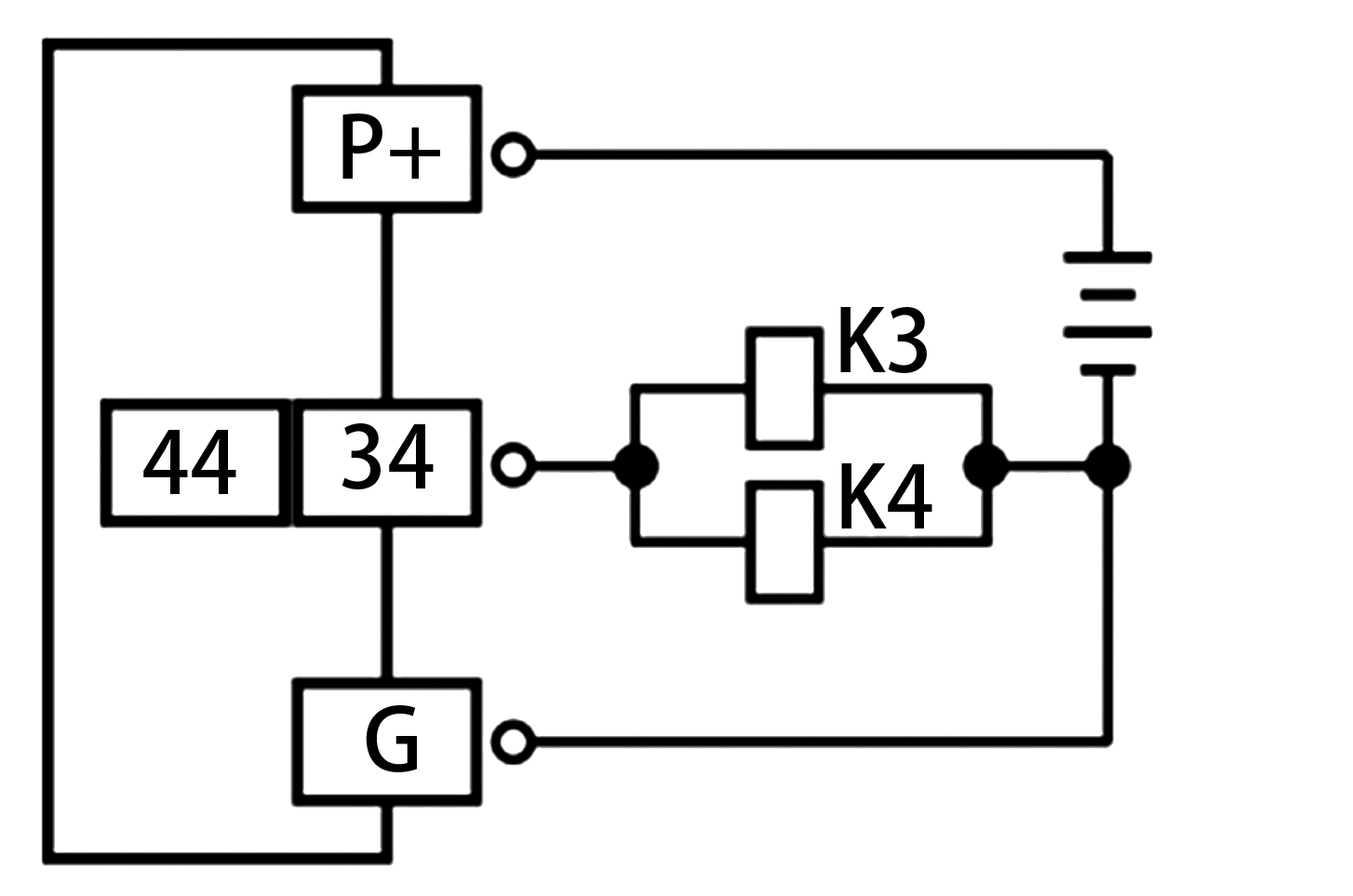

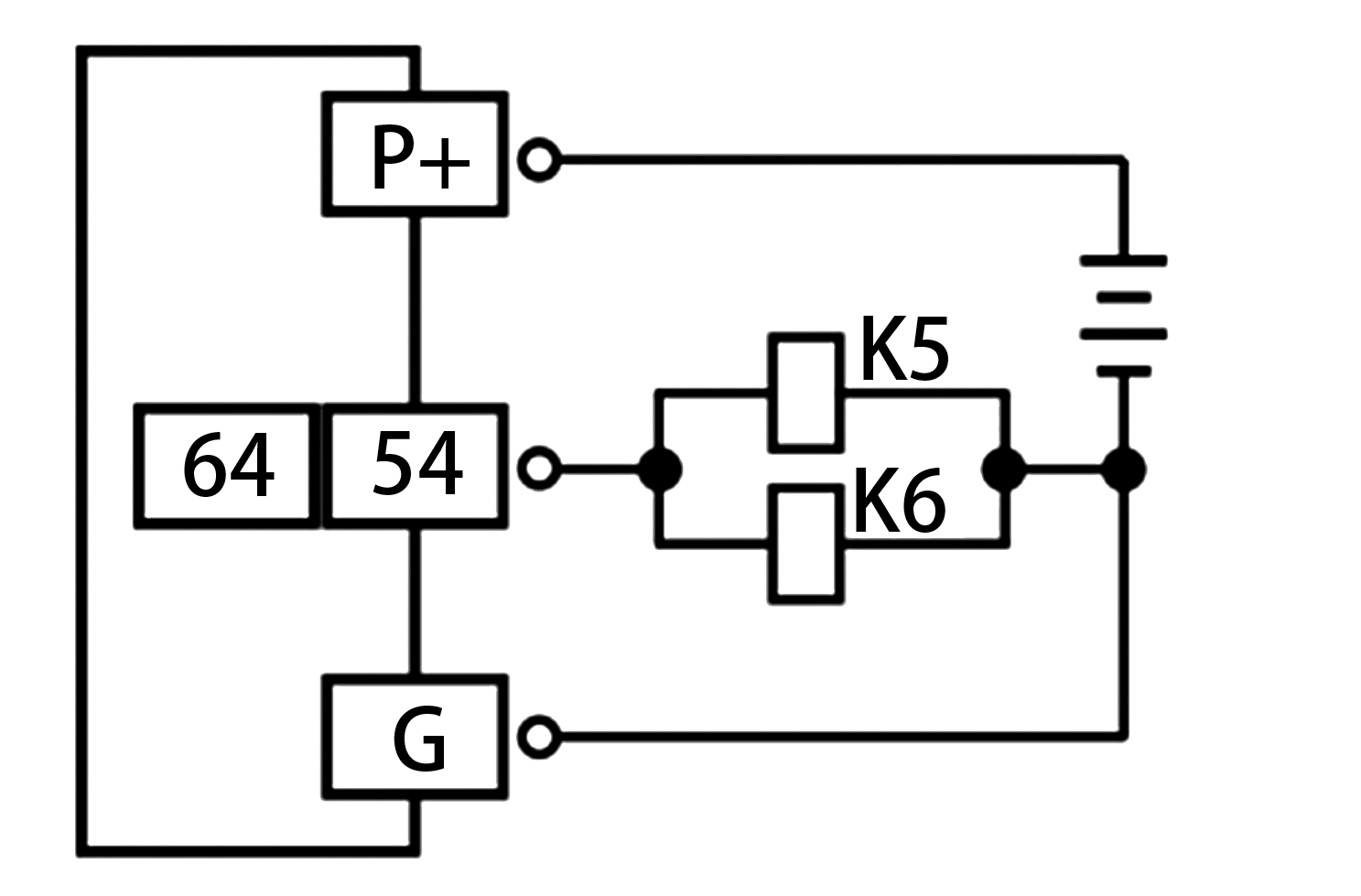

functional block diagram | Typical application |

|

|

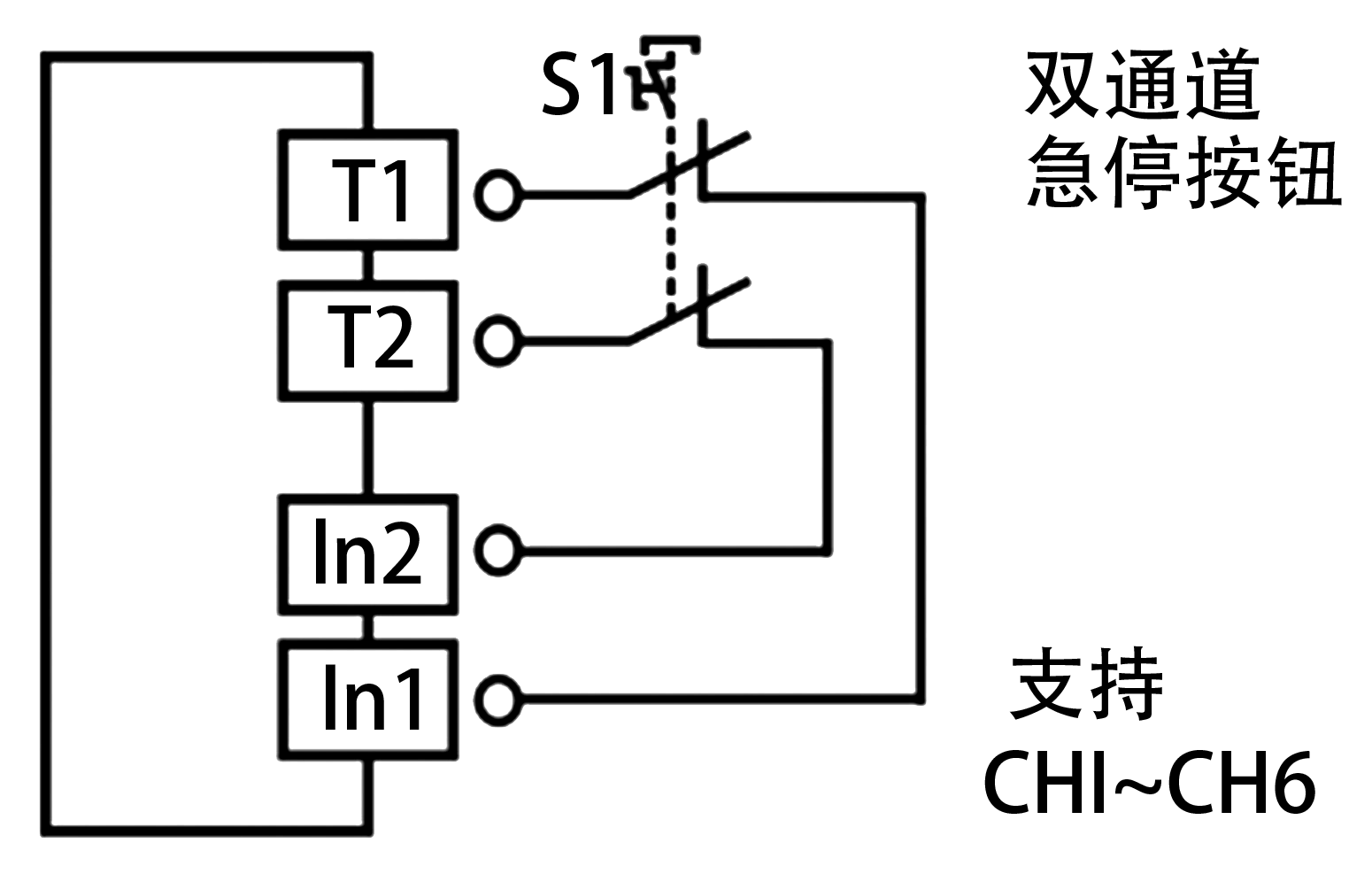

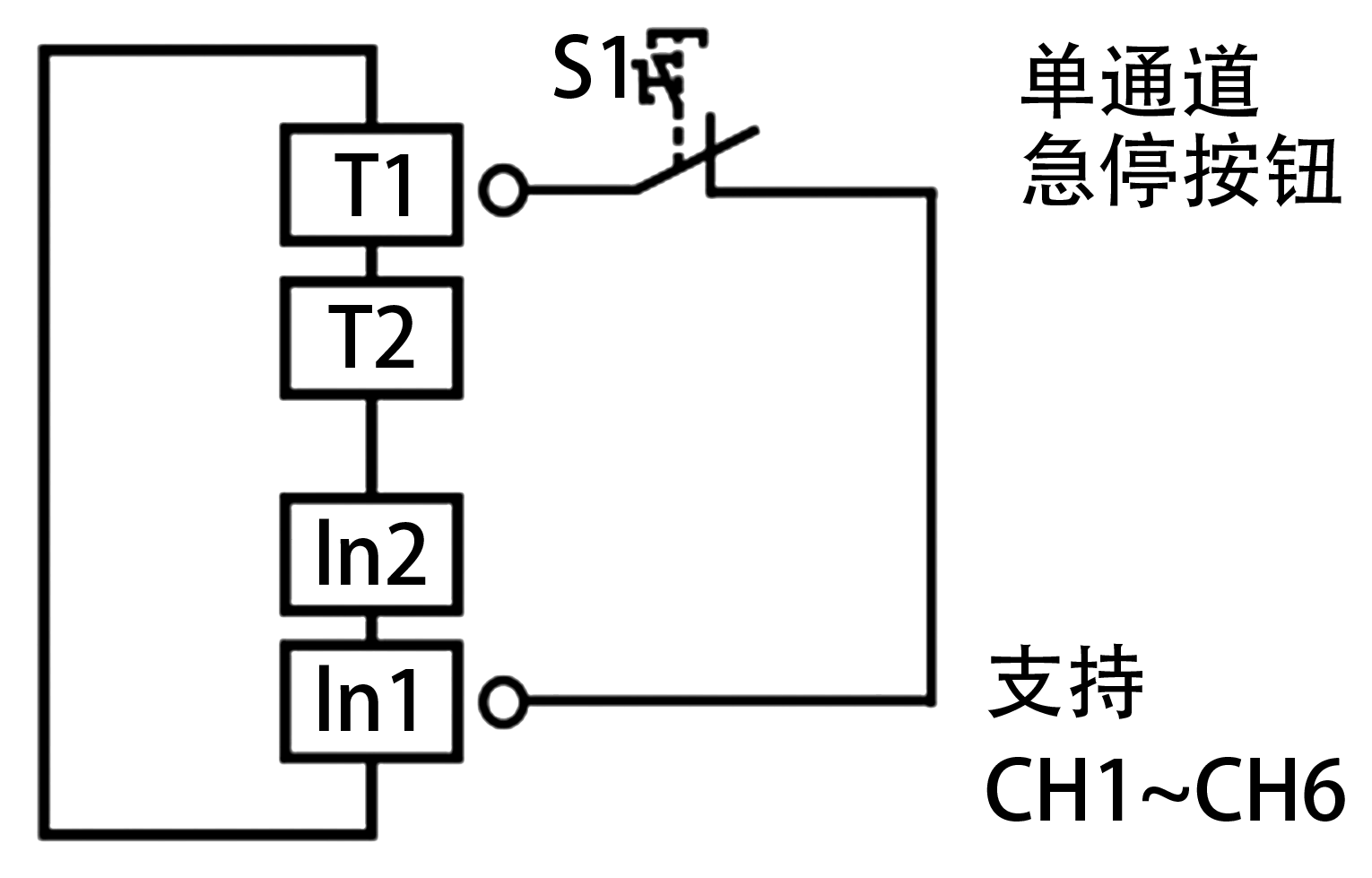

Input element: CH1 (emergency stop button); CH2 (emergency stop button); CH3 (reset button) Input element: CH4 (emergency stop button); CH5 (emergency stop button); CH6 (reset button) Control logic: CH1&CH2CH4&CH5 Reset mode: manual reset output delay: 0s. Safety level: Cat.4 performance level: PLe safety integrity level: SIL 3 |

| ▊ | Wiring diagram |

Power Supply |

| correspondence |  |

input |  |  |  |

|  | ||

|  | ||

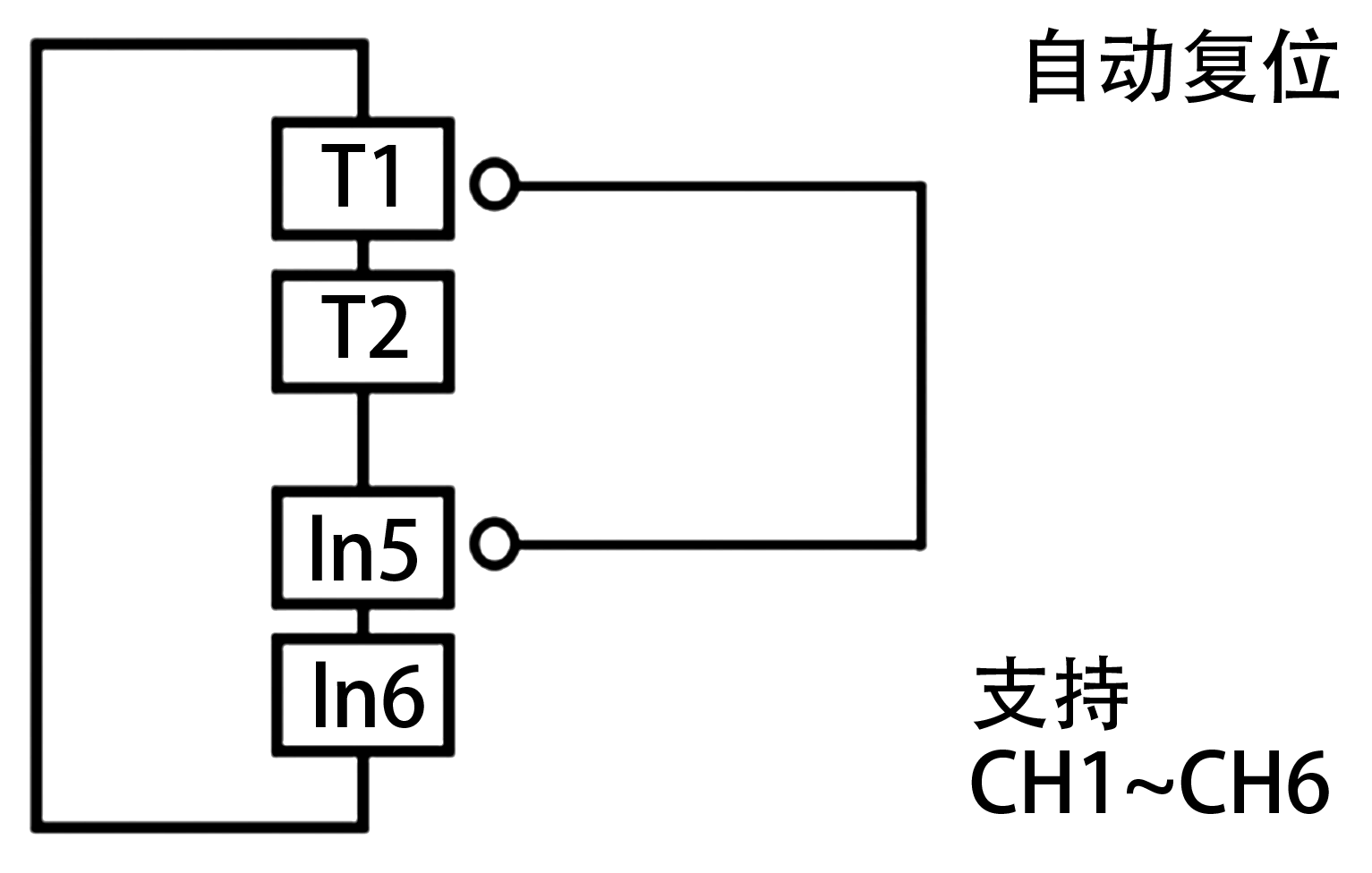

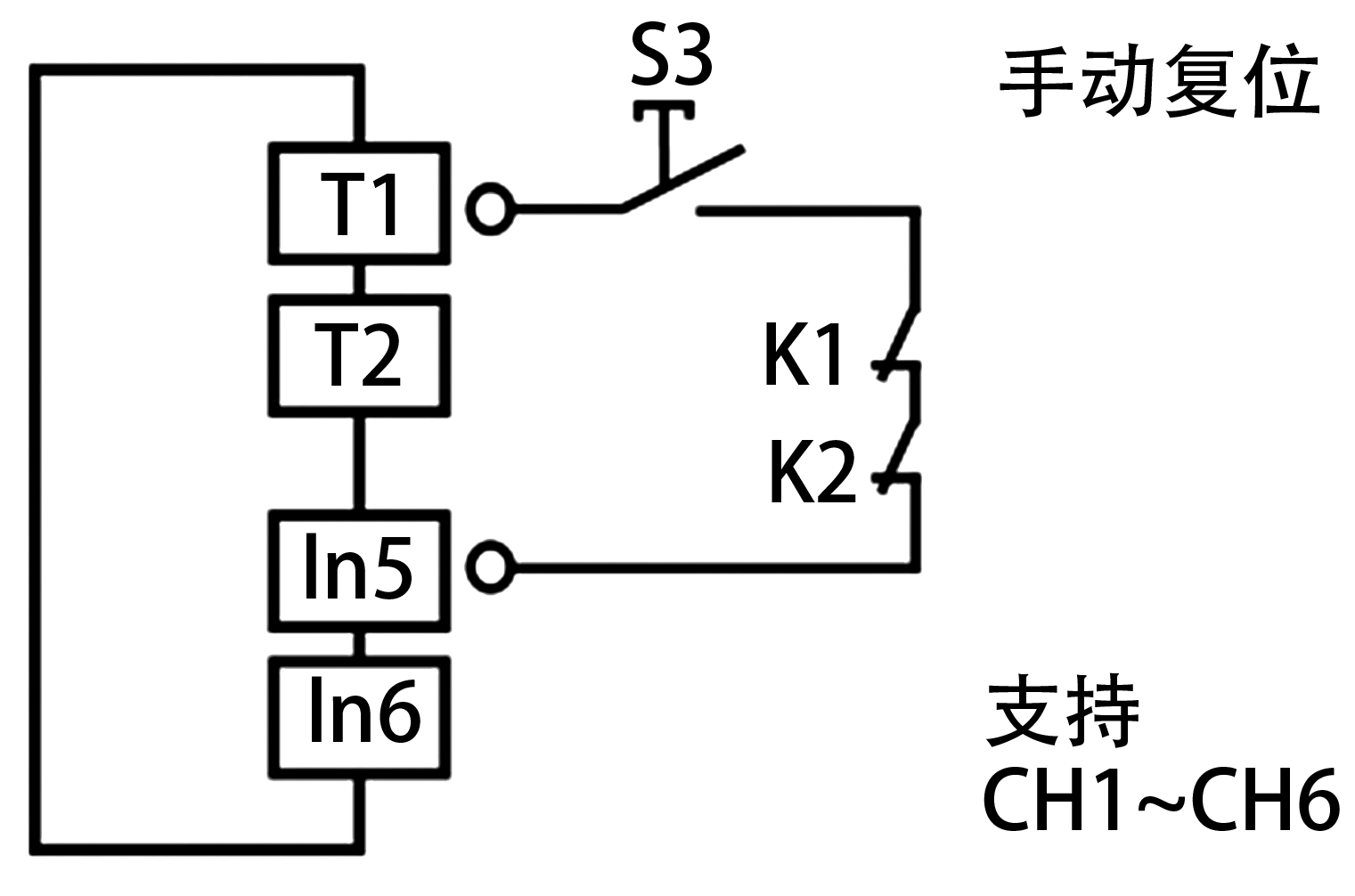

reset |  |  | |

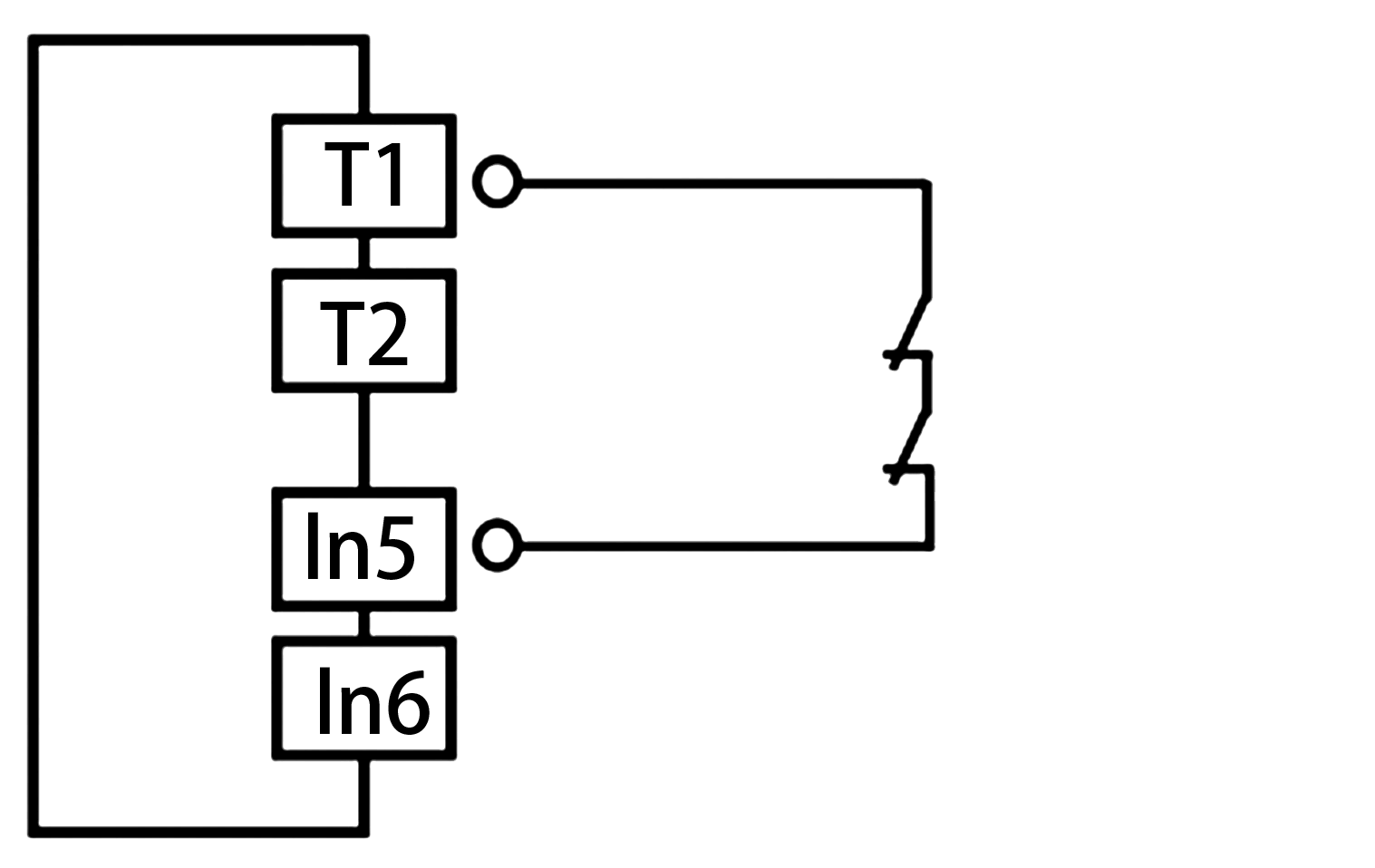

feedback |  |  | |

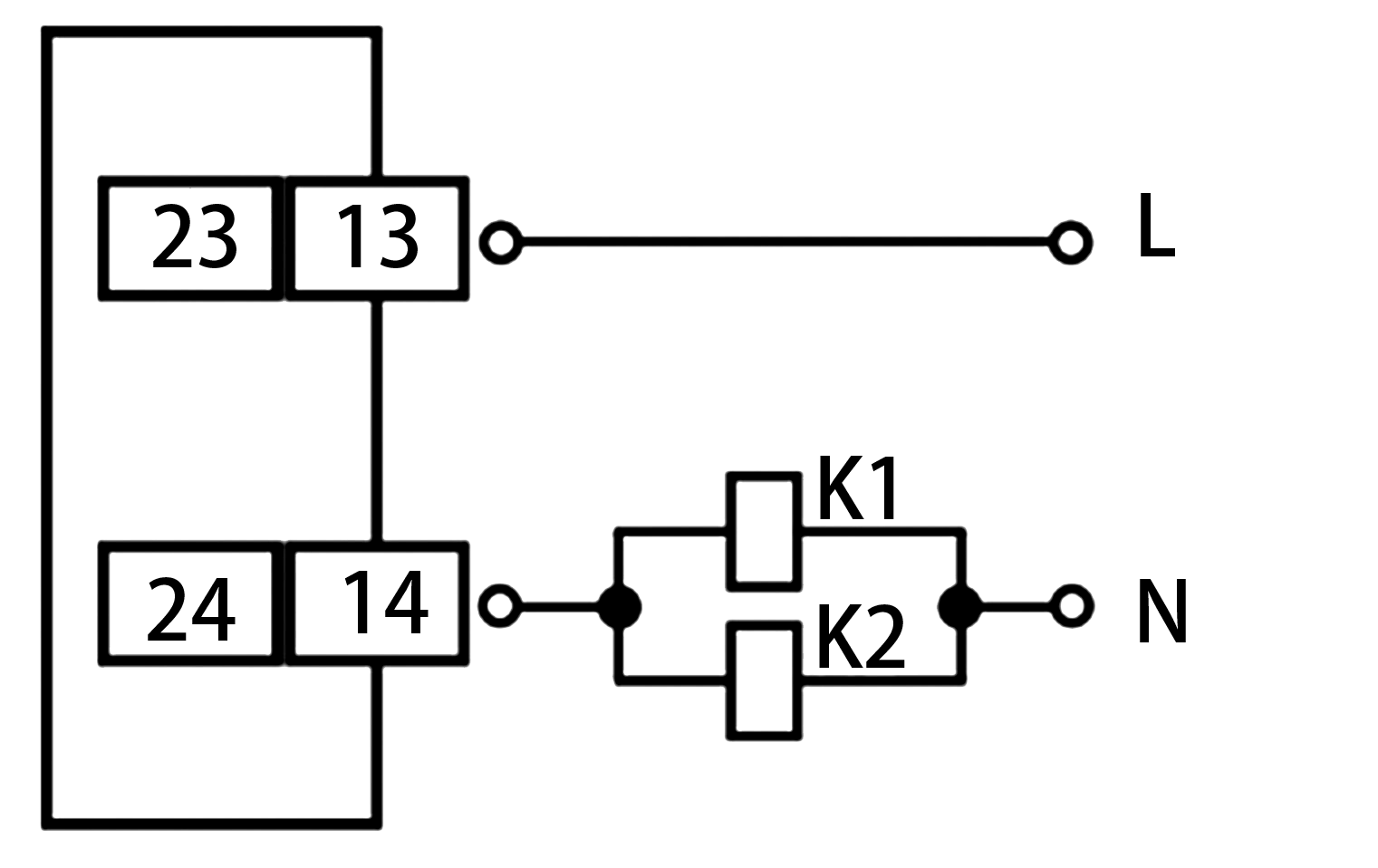

output |  |  |  |

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright © Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing