According to OSHA, 85 people in North America have been killed, 34900 seriously injured and 61800 slightly injured in forklift accidents.

However, in China, there are a large number of vicious accidents such as scratch, collision, rolling and collision caused by blind area, fatigue, overspeed and steering, which have resulted in production stoppage, large amount of compensation and leaders' pursuit of responsibility. So. Forklift anti-collision is one of the important means of forklift safety management;

Why do forklift accidents happen frequently? What's the reason

1. Blind area of forklift vision: on the one hand, the structure blocks the vision when backing up; on the other hand, the high stacking of goods blocks the driver's vision, and does not pay attention to collision with people.

2. Improper operation of the driver: the forklift impacts the wall or objects after normal driving or losing control, and the driver's body stretches out of the vehicle, causing an accident.

Please alert and drive the forklift carefully!

3. No one is allowed to approach the forklift within 1.5m of the operating range specified for installation

When backing up a forklift, the driver must first find out the surrounding conditions and confirm the safety before backing up;

When backing up at the workshop, warehouse, narrow road and other places, there should be someone standing at the driver's side to command.

The above illustration is in violation of the correct operation regulations, leading to the occurrence of accidents.

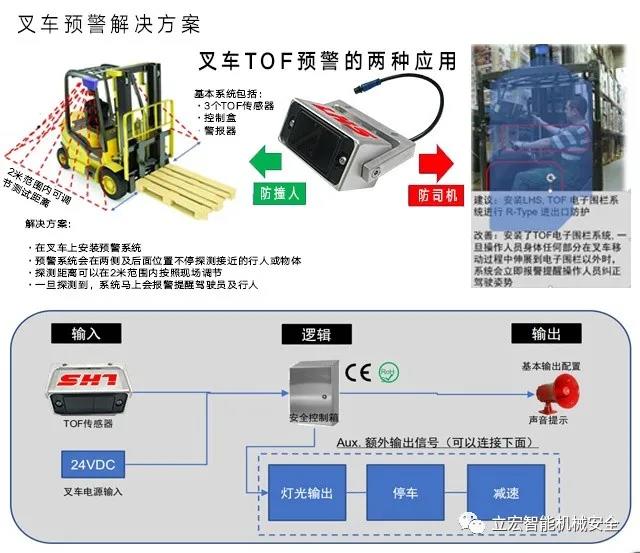

Forklift warning solutions:

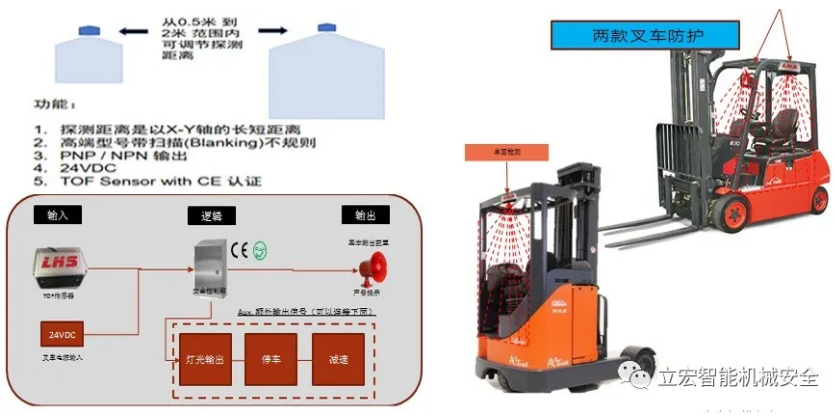

Forklift warning sensor parameters.

| Excellent early warning and detection ability, not affected by reflection Independent setting of detection area Strong resistance to ambient light • detection area: 2000-2000 (settable) • 3D TOF will trigger an alarm if there is an obstacle |

| Product selection | |||

| Product name | model | Detection distance | Order No |

| 3d-tof-forklift warning sensor | 3D-TOF-WK-5M | 最大:2米-2米 | CCTO-9011 |

| Lot IOT collector | 3D-TOF-CJ03 | 4g-5g Internet of things | CCTO-9021 |

| explain | |||

First installation mode:

The sensor is installed on the left and right side of the forklift as well as the back side. It constantly detects the surrounding objects and pedestrians within 2m. If it detects the system, it will give an alarm to remind the driver and pedestrians.

The second installation mode:

Sensor installation is applicable to ordinary forklift and R-type forklift. When the driver reaches out of the vehicle and triggers the sensor, the alarm and deceleration stop functions can be realized (it is recommended to use after risk assessment)

Design principle: (in case of forklift accident, it is relatively safer to keep the driver's body in the driver's cabin)

N the first warning function: during normal driving, avoid the driver's body extending out of the driving cabin at will, prompt the driver to regulate the operation behavior correctly, and avoid the accident of body extending and collision to the shelf.

N the second stop deceleration function: (it is recommended to conduct safety assessment): when the forklift is out of control, the door of the driver's cabin may collide with the wall, and the driver instinctively reaches out to block it. If this system is available, the forklift will stop immediately after the driver reaches out, so as to ensure the safety of the driver.

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright © Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing